Future-Proofing Your Operations with Advanced Aluminum Tube Evaporators

Future-Proofing Your Operations with Advanced Aluminum Tube Evaporators Table of Contents 1. Understanding Evaporators and Their Role in Industry 2. What are Aluminum Tube Evaporators? 3. Key Advantages of Advanced Aluminum Tube Evaporators 3.1 Superior Thermal Efficiency 3.2 Lightweight and Durable Design 3.3 Corrosion Resistance 4. How Aluminum Tube Evaporators Enhance Operationa

Published:

2026-02-18

source:

author:

Future-Proofing Your Operations with Advanced Aluminum Tube Evaporators

Table of Contents

1. Understanding Evaporators and Their Role in Industry

2. What are Aluminum Tube Evaporators?

3. Key Advantages of Advanced Aluminum Tube Evaporators

3.1 Superior Thermal Efficiency

3.2 Lightweight and Durable Design

3.3 Corrosion Resistance

4. How Aluminum Tube Evaporators Enhance Operational Flexibility

5. Future Trends in Evaporator Technology

6. Selecting the Right Aluminum Tube Evaporator for Your Needs

7. Installation and Maintenance Best Practices

8. Frequently Asked Questions about Aluminum Tube Evaporators

9. Conclusion

1. Understanding Evaporators and Their Role in Industry

Evaporators are essential equipment used in various industrial processes to separate liquids from solids or to concentrate solutions. They play a vital role in industries such as food and beverage, pharmaceuticals, and chemical manufacturing. By transforming liquid into vapor, evaporators enable efficient processing, facilitate product concentration, and aid in recycling materials. Understanding the function and importance of these devices can significantly impact operational efficiency and cost-effectiveness.

2. What are Aluminum Tube Evaporators?

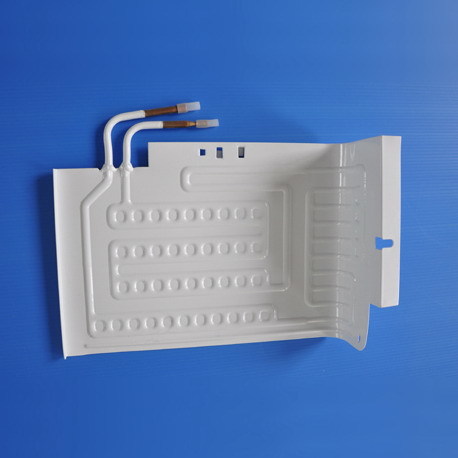

Aluminum tube evaporators are specialized heat exchange devices designed for efficient thermal transfer during the evaporation process. Made from high-quality aluminum, these evaporators utilize a tubular design that maximizes surface area for heat transfer, making them an optimal choice for many industrial applications. The lightweight nature of aluminum combined with its impressive thermal conductivity ensures that these evaporators can handle various applications while maintaining efficiency and reliability.

3. Key Advantages of Advanced Aluminum Tube Evaporators

The adoption of advanced aluminum tube evaporators in industrial settings is driven by their numerous benefits, which include:

3.1 Superior Thermal Efficiency

Advanced aluminum tube evaporators are engineered for great thermal performance. Their design allows for efficient heat transfer, leading to reduced energy consumption and improved operational efficiency. This feature is particularly crucial in industries where energy costs can significantly impact the bottom line.

3.2 Lightweight and Durable Design

One of the standout characteristics of aluminum tube evaporators is their lightweight construction. This feature not only simplifies installation but also reduces the overall load on supporting structures. Despite being lightweight, aluminum is exceptionally durable, offering long-lasting performance under various operational conditions.

3.3 Corrosion Resistance

Aluminum inherently possesses resistance to corrosion, making it an excellent choice for environments that may expose equipment to moisture and various chemicals. This resistance extends the lifespan of evaporators and reduces maintenance costs associated with corrosion-related failures.

4. How Aluminum Tube Evaporators Enhance Operational Flexibility

The design and versatility of aluminum tube evaporators allow them to adapt to various operational needs. Industries can benefit from their ability to handle different materials and processes. Whether it's for concentrating fruit juices or recovering solvents in chemical processes, these evaporators can be tailored to meet specific requirements, ensuring that operations remain efficient as market demands evolve.

5. Future Trends in Evaporator Technology

As industries continue to innovate, so too do the technologies associated with evaporators. Key trends include:

- **Increased Automation**: The integration of automation technologies is enhancing the control and efficiency of evaporators. Smart systems enable real-time monitoring and adjustments, leading to optimized performance.

- **Sustainability Focus**: There is an increasing emphasis on environmentally friendly designs, with manufacturers exploring materials and processes that minimize energy consumption and waste generation.

- **Advanced Materials**: As research progresses, new materials that further improve thermal conductivity and corrosion resistance are being developed, promising even greater efficiency.

6. Selecting the Right Aluminum Tube Evaporator for Your Needs

Choosing the appropriate aluminum tube evaporator for your specific application involves considering several factors:

- **Application Requirements**: Assess the specific needs of your process, including the type of material being evaporated and the desired concentration levels.

- **Capacity Needs**: Evaluate the scale of your operations to determine the necessary evaporator capacity.

- **Energy Efficiency**: Look for evaporators designed with energy efficiency in mind to minimize operational costs.

Consulting with manufacturers and experts can provide invaluable insights into selecting the right unit tailored to your operations.

7. Installation and Maintenance Best Practices

Proper installation and regular maintenance are critical to ensuring the long-term performance of aluminum tube evaporators. Here are some best practices:

- **Professional Installation**: Engage experienced professionals to install the evaporator, ensuring compliance with industry standards and regulations.

- **Regular Inspections**: Schedule routine inspections to identify any potential issues before they escalate.

- **Cleaning Protocols**: Establish cleaning protocols to remove residues and prevent scaling, which can hinder performance.

Implementing these practices will help maintain efficiency and prolong the lifespan of your evaporator system.

8. Frequently Asked Questions about Aluminum Tube Evaporators

**1. What industries commonly use aluminum tube evaporators?**

Aluminum tube evaporators are widely used in the food and beverage, pharmaceutical, and chemical sectors due to their efficiency and versatility.

**2. How do aluminum tube evaporators compare to traditional models?**

They provide better thermal efficiency, are lighter, and have superior corrosion resistance compared to traditional evaporators.

**3. Can aluminum tube evaporators handle corrosive materials?**

Yes, aluminum offers excellent corrosion resistance, making it suitable for various applications.

**4. What is the typical lifespan of an aluminum tube evaporator?**

With proper maintenance, aluminum tube evaporators can last several years, often longer than units made from other materials.

**5. Are there energy efficiency standards for evaporators?**

Yes, many regions have established energy efficiency standards that manufacturers must comply with, ensuring that the equipment is designed to minimize energy consumption.

9. Conclusion

In an ever-evolving industrial landscape, future-proofing operations is essential for sustained success. Advanced aluminum tube evaporators emerge as a pivotal technology, offering unmatched thermal efficiency, lightweight construction, and exceptional corrosion resistance. By embracing these innovative devices, industries can enhance operational flexibility and adapt to changing market demands. Selecting the right evaporator, coupled with proper installation and maintenance practices, ensures that your operations remain competitive and efficient for years to come. Investing in advanced aluminum tube evaporators is not just a decision for today but a strategic move towards a sustainable and resilient future.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.