Understanding Aluminum Fin Evaporators: Key Insights into Heat Exchanger Efficiency

Aluminum fin evaporators are crucial components in various industrial heat exchange systems. They play a pivotal role in cooling processes by facilitating the transfer of heat between two fluids, which is essential in applications such as refrigeration and air conditioning. Understanding their design and functionality can significantly enhance system efficiency and reliability. The primary functio

Published:

2026-01-28

source:

author:

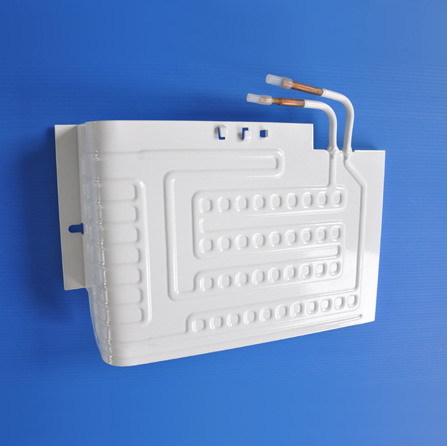

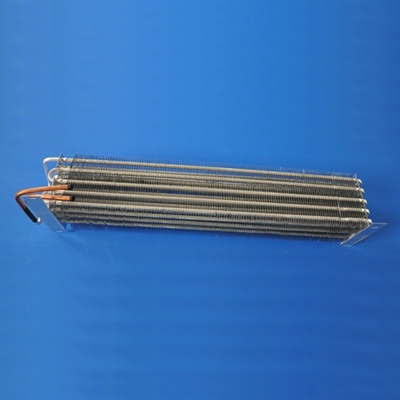

Aluminum fin evaporators are crucial components in various industrial heat exchange systems. They play a pivotal role in cooling processes by facilitating the transfer of heat between two fluids, which is essential in applications such as refrigeration and air conditioning. Understanding their design and functionality can significantly enhance system efficiency and reliability.

The primary function of an aluminum fin evaporator is to absorb heat from the environment or a specific medium, thereby cooling the fluid that circulates through it. The fins, made from aluminum, are integral to this process. Aluminum is chosen for its excellent thermal conductivity, which allows for efficient heat transfer. Additionally, the lightweight nature of aluminum makes it easier to install and maintain, thus reducing overall operational costs.

One significant advantage of using an aluminum fin evaporator is its enhanced surface area. The fins increase the contact area between the refrigerant and the surrounding air, improving the heat exchange process. This results in more effective cooling, which is particularly beneficial in high-demand applications. Furthermore, the design of these evaporators can be tailored to meet specific requirements, including varying sizes, shapes, and fin configurations, allowing for flexibility in industrial setups.

Maintenance is a crucial aspect of ensuring the longevity and efficiency of aluminum fin evaporators. Regular cleaning is essential to prevent dust and debris from accumulating on the fins, as this can hinder airflow and reduce cooling efficiency. Additionally, periodic inspections for any signs of corrosion or damage can help identify issues before they escalate, ensuring optimal performance throughout the evaporator's lifespan.

When selecting an aluminum fin evaporator, consider factors such as the intended application, fluid characteristics, and environmental conditions. Understanding these parameters will help in choosing the right size and configuration, ultimately enhancing the system's overall efficacy.

In conclusion, aluminum fin evaporators are an indispensable part of industrial heat exchange systems. Their efficiency and adaptability make them suitable for various applications, from commercial refrigeration to industrial cooling processes. By understanding their operation and maintaining them properly, users can significantly improve heat transfer efficiency and prolong the lifespan of their cooling systems. Whether you're upgrading an existing system or designing a new one, aluminum fin evaporators offer a reliable solution for heat exchange needs.

The primary function of an aluminum fin evaporator is to absorb heat from the environment or a specific medium, thereby cooling the fluid that circulates through it. The fins, made from aluminum, are integral to this process. Aluminum is chosen for its excellent thermal conductivity, which allows for efficient heat transfer. Additionally, the lightweight nature of aluminum makes it easier to install and maintain, thus reducing overall operational costs.

One significant advantage of using an aluminum fin evaporator is its enhanced surface area. The fins increase the contact area between the refrigerant and the surrounding air, improving the heat exchange process. This results in more effective cooling, which is particularly beneficial in high-demand applications. Furthermore, the design of these evaporators can be tailored to meet specific requirements, including varying sizes, shapes, and fin configurations, allowing for flexibility in industrial setups.

Maintenance is a crucial aspect of ensuring the longevity and efficiency of aluminum fin evaporators. Regular cleaning is essential to prevent dust and debris from accumulating on the fins, as this can hinder airflow and reduce cooling efficiency. Additionally, periodic inspections for any signs of corrosion or damage can help identify issues before they escalate, ensuring optimal performance throughout the evaporator's lifespan.

When selecting an aluminum fin evaporator, consider factors such as the intended application, fluid characteristics, and environmental conditions. Understanding these parameters will help in choosing the right size and configuration, ultimately enhancing the system's overall efficacy.

In conclusion, aluminum fin evaporators are an indispensable part of industrial heat exchange systems. Their efficiency and adaptability make them suitable for various applications, from commercial refrigeration to industrial cooling processes. By understanding their operation and maintaining them properly, users can significantly improve heat transfer efficiency and prolong the lifespan of their cooling systems. Whether you're upgrading an existing system or designing a new one, aluminum fin evaporators offer a reliable solution for heat exchange needs.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.