Maximizing Performance with Aluminum Fin Evaporators: A Comprehensive Guide

Maximizing Performance with Aluminum Fin Evaporators: A Comprehensive Guide Table of Contents 1. Introduction to Aluminum Fin Evaporators 2. Understanding Aluminum Fin Evaporators 3. Advantages of Aluminum Fin Evaporators 4. Design and Configuration of Aluminum Fin Evaporators 5. Maintenance Best Practices for Longevity 6. Applications in Industrial Settings 7. Trouble

Published:

2026-02-04

source:

author:

Maximizing Performance with Aluminum Fin Evaporators: A Comprehensive Guide

Table of Contents

- 1. Introduction to Aluminum Fin Evaporators

- 2. Understanding Aluminum Fin Evaporators

- 3. Advantages of Aluminum Fin Evaporators

- 4. Design and Configuration of Aluminum Fin Evaporators

- 5. Maintenance Best Practices for Longevity

- 6. Applications in Industrial Settings

- 7. Troubleshooting Common Issues

- 8. Conclusion

1. Introduction to Aluminum Fin Evaporators

Aluminum fin evaporators play a crucial role in various industrial applications, particularly in the realm of heat exchange. With their efficient thermal conductivity and lightweight properties, these evaporators are designed to enhance the performance of cooling systems. As industries continually seek ways to optimize energy consumption and reduce costs, understanding how to maximize the performance of aluminum fin evaporators becomes essential.

2. Understanding Aluminum Fin Evaporators

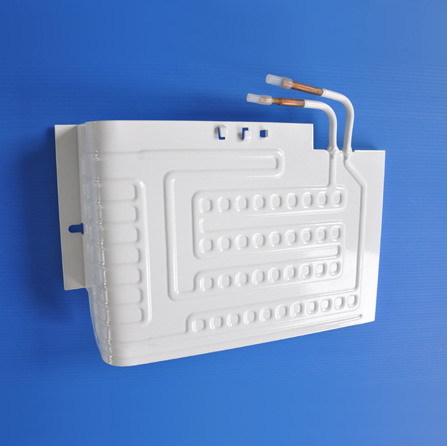

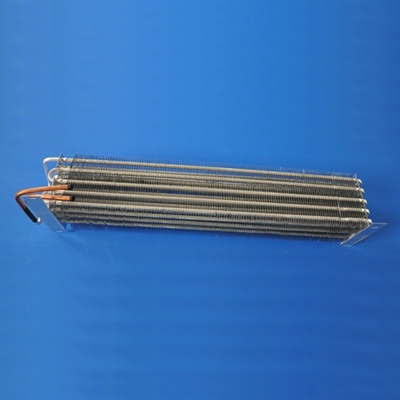

Aluminum fin evaporators consist of a series of fins attached to a core unit. The design allows for increased surface area, enhancing the heat transfer capabilities of the unit. They operate by absorbing heat from the surrounding environment, which causes the refrigerant inside the evaporator to evaporate and cool the air or fluid passing over the fins.

The aluminum fins are essential for efficient heat exchange, as they facilitate a larger contact area between the refrigerant and the air, ensuring more effective cooling. With various designs available, including plate, coil, and fin arrangements, selecting the appropriate type for specific applications is crucial for optimal performance.

2.1 Key Components of Aluminum Fin Evaporators

The main components of aluminum fin evaporators include:

- **Fins**: Made of aluminum, these components increase the surface area for heat transfer.

- **Core**: The central part where the refrigerant circulates.

- **Expansion Valve**: Regulates the flow of refrigerant into the evaporator.

- **Fans**: Aid in circulating air over the fins, enhancing heat transfer.

3. Advantages of Aluminum Fin Evaporators

Understanding the advantages of aluminum fin evaporators can help industries make informed decisions regarding their heat exchange systems.

3.1 High Thermal Conductivity

Aluminum has excellent thermal conductivity, allowing for efficient heat transfer. This means that aluminum fin evaporators can achieve lower temperatures more quickly than many other materials.

3.2 Lightweight and Compact Design

One of the most significant benefits of aluminum fin evaporators is their lightweight design. This feature simplifies installation and reduces the structural support requirements, making them ideal for various applications where space and weight are concerns.

3.3 Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion. This durability ensures a longer lifespan for evaporators, reducing the need for frequent replacements and minimizing maintenance costs.

3.4 Versatility

Aluminum fin evaporators are versatile and can be tailored to fit different industrial applications, from refrigeration units to air conditioning systems. Their adaptability allows for customized solutions based on specific cooling requirements.

4. Design and Configuration of Aluminum Fin Evaporators

The design and configuration of aluminum fin evaporators are critical to their efficiency and performance. Several factors should be considered when selecting or designing these components.

4.1 Fin Design

The design of the fins, including their thickness and spacing, affects heat transfer efficiency. Wider fins can increase surface area but may also lead to airflow restriction. Balancing these factors is essential for optimal performance.

4.2 Core Configuration

The core configuration, whether it is a flooded or dry evaporator design, impacts the performance of the unit. Flooded evaporators have a higher heat transfer efficiency but require more refrigeration, while dry evaporators are more straightforward and often used in smaller systems.

4.3 Airflow Management

Proper airflow management is vital for maximizing the effectiveness of aluminum fin evaporators. Ensuring that fans or blowers are correctly sized and positioned can prevent hot spots and promote uniform cooling across the entire surface area.

4.4 Integration with Other Components

Careful consideration should be given to how aluminum fin evaporators integrate with existing systems. Ensuring compatibility and efficient operation with compressors, condensers, and other components enhances overall system performance.

5. Maintenance Best Practices for Longevity

Regular maintenance is crucial for ensuring the longevity and efficiency of aluminum fin evaporators. Implementing best practices can help prevent costly downtime and extend the life of the equipment.

5.1 Regular Cleaning

Dirt and debris can accumulate on the fins, obstructing airflow and reducing heat transfer efficiency. Regular cleaning, using gentle methods to avoid damaging the fins, is essential to maintain optimal performance.

5.2 Inspection for Damage

Routine inspections should be conducted to identify any potential issues, such as leaks or corrosion. Early detection can prevent more significant problems from developing and ensure the evaporator continues to operate efficiently.

5.3 Refrigerant Level Checks

Regularly checking the refrigerant levels is critical. Low refrigerant can lead to poor performance and potential damage to the system. Maintaining the correct levels ensures effective heat exchange.

5.4 Professional Servicing

Engaging professional technicians for periodic servicing can help identify hidden problems and provide solutions that may not be apparent through regular inspections. Their expertise can enhance the performance and lifespan of aluminum fin evaporators.

6. Applications in Industrial Settings

Aluminum fin evaporators are widely used across various industrial sectors due to their efficiency and adaptability.

6.1 Food and Beverage Industry

In the food and beverage industry, maintaining precise temperatures is crucial for product quality and safety. Aluminum fin evaporators are commonly used in refrigeration units for both storage and processing areas.

6.2 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems utilize aluminum fin evaporators for their compact design and efficient cooling capabilities, making them ideal for residential and commercial applications.

6.3 Chemical Processing

In chemical processing, precise temperature control is critical to ensure product consistency and safety. Aluminum fin evaporators provide reliable cooling in these settings, helping maintain optimal operating conditions.

6.4 Pharmaceuticals

The pharmaceutical industry often requires stringent temperature controls to maintain the integrity of products. Aluminum fin evaporators ensure reliable cooling in sensitive environments, helping to manage the intricate temperature requirements of pharmaceutical storage.

7. Troubleshooting Common Issues

Even with regular maintenance, issues may arise with aluminum fin evaporators. Understanding common problems and their solutions is essential for maintaining system performance.

7.1 Insufficient Cooling

If an evaporator is not providing adequate cooling, potential causes may include low refrigerant levels, clogged filters, or poor airflow. Identifying the root cause is crucial for effective troubleshooting.

7.2 Noise Issues

Unusual noises can indicate problems with fans or internal components. Inspecting for loose parts or misalignment can often resolve these issues.

7.3 Ice Formation

Ice buildup on evaporators can hinder performance. This often occurs due to low refrigerant levels or insufficient airflow. Regular checks and maintenance can help prevent ice formation.

7.4 Leaks

Identifying and repairing leaks promptly is crucial. Regular inspections should include checks for refrigerant leaks, as these can lead to decreased efficiency and environmental concerns.

8. Conclusion

Maximizing the performance of aluminum fin evaporators is essential for ensuring efficient heat exchange across various industrial applications. By understanding their design, advantages, and maintenance practices, industries can achieve optimal cooling performance while minimizing costs and enhancing equipment longevity. Through diligent maintenance and awareness of common issues, organizations can ensure that their aluminum fin evaporators continue to operate at peak efficiency, thereby contributing to overall operational success. Taking the time to invest in these systems not only provides immediate benefits but also supports long-term sustainability in industrial operations.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.