Innovative Design Considerations for Rollbond Plates in Cooling Systems

Innovative Design Considerations for Rollbond Plates in Cooling Systems Introduction to Rollbond Plates in Cooling Systems In the realm of **industrial cooling systems**, Rollbond plates have emerged as a pivotal component designed for efficiency and performance. These unique plates utilize innovative bonding techniques to create lightweight, compact, and highly effective solutions for heat exchan

Published:

2026-01-21

source:

author:

Innovative Design Considerations for Rollbond Plates in Cooling Systems

Introduction to Rollbond Plates in Cooling Systems

In the realm of **industrial cooling systems**, Rollbond plates have emerged as a pivotal component designed for efficiency and performance. These unique plates utilize innovative bonding techniques to create lightweight, compact, and highly effective solutions for heat exchange. As we delve deeper into the design considerations that make Rollbond plates invaluable, we will explore their structural advantages, thermal performance, and applications in various cooling systems.

What are Rollbond Plates?

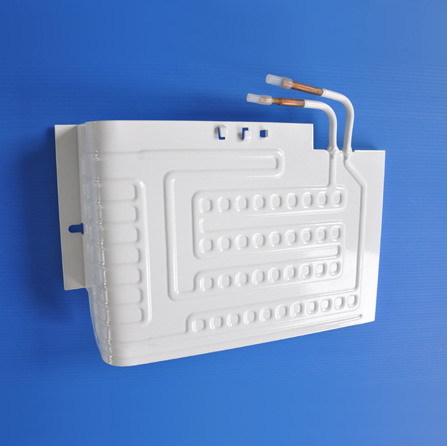

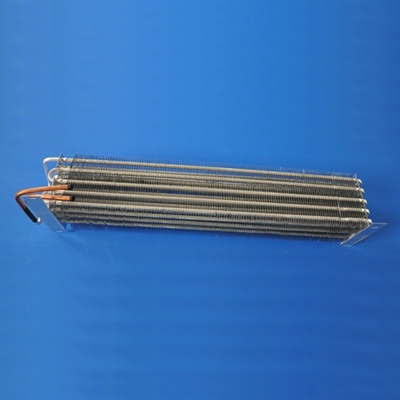

Definition and Composition

Rollbond plates, generally composed of aluminum or other lightweight metals, are engineered to optimize heat transfer in cooling applications. Utilizing a patented process, these plates feature a series of **bonded channels** formed through the rolling technique, enhancing their surface area for improved thermal efficiency.

Historical Context and Development

The concept of Rollbond technology has its roots in the growing need for energy-efficient cooling solutions. Over the past few decades, advancements in materials science and manufacturing processes have allowed for the refinement of Rollbond technology, resulting in plates that are not only effective but also more environmentally friendly.

Key Advantages of Rollbond Plates

Enhanced Thermal Efficiency

One of the most significant benefits of Rollbond plates is their **superior thermal conductivity**. The design enables a larger surface area for heat exchange, which significantly improves the overall efficiency of cooling systems. This efficiency translates to lower energy consumption and reduced operational costs.

Lightweight and Compact Design

Rollbond plates boast a lightweight profile, which makes them ideal for a variety of applications, particularly where space is at a premium. Their compact design allows for easier installation and integration into existing systems, making them a versatile choice for engineers and designers.

Corrosion Resistance and Longevity

The materials used in Rollbond plate construction are often treated to resist corrosion, ensuring longevity and reliability. This durability is crucial in industrial environments where exposure to harsh conditions is common.

Innovative Design Considerations

Material Selection for Optimal Performance

Choosing the right materials is fundamental to the performance of Rollbond plates. Aluminum is the most common choice due to its lightweight nature and excellent thermal properties. However, advancements in alloys and coatings are opening new avenues for enhancing durability and efficiency.

Channel Design and Geometry

The geometry of the channels within Rollbond plates plays a critical role in their performance. Innovative designs that incorporate varying channel sizes and shapes can further enhance heat transfer rates. **Custom channel designs** tailored to specific cooling requirements can result in improved system performance.

Integration with Advanced Control Systems

Incorporating Rollbond plates into cooling systems can be significantly enhanced by compatibility with advanced **control systems**. Smart technology that monitors and adjusts cooling performance in real-time can lead to optimized energy usage and improved operational efficiency.

Applications of Rollbond Plates in Cooling Systems

Industrial Refrigeration

In industrial refrigeration, Rollbond plates are utilized in systems that demand high efficiency and reliability. Their compact design and superior thermal performance make them ideal for **refrigeration units**, ensuring consistent cooling under varying loads.

Air Conditioning Systems

Rollbond technology has found its way into modern air conditioning systems, where the need for efficiency is paramount. By enhancing the heat exchange process, Rollbond plates contribute to lower energy consumption and improved cooling effectiveness.

Heat Pumps

In heat pump applications, Rollbond plates provide an efficient means of transferring heat. Their innovative design allows for compact installations, making them suitable for residential and commercial heating and cooling solutions.

Challenges and Solutions in Rollbond Plate Design

Manufacturing Challenges

The manufacturing of Rollbond plates can pose challenges, particularly regarding maintaining the integrity of the bonding process. Ensuring uniformity and strength in the bonded channels is critical for optimal performance.

Addressing Thermal Expansion

Thermal expansion can affect the performance of Rollbond plates. Engineers must consider the materials used and their response to temperature variations to mitigate issues related to expansion and contraction.

Future Trends in Rollbond Technology

Emerging Materials and Techniques

As research progresses, new materials and manufacturing techniques are emerging. Innovations such as **composite materials** and enhanced coatings will likely improve the performance of Rollbond plates even further, pushing the boundaries of efficiency.

Sustainability in Design

With a growing emphasis on sustainability, future designs will likely focus on eco-friendly materials and processes. This shift will not only enhance the environmental footprint of Rollbond technology but also appeal to a market increasingly concerned with sustainability.

Conclusion

In conclusion, Rollbond plates represent a significant advancement in cooling system design, offering unparalleled efficiency, durability, and adaptability. As the industry moves toward more innovative and sustainable solutions, the importance of understanding the design considerations of Rollbond technology cannot be overstated. By investing in these advanced plates, companies can enhance their cooling systems, reduce energy costs, and improve overall performance.

Frequently Asked Questions

1. What are the key benefits of using Rollbond plates in cooling systems?

Rollbond plates provide enhanced thermal efficiency, a lightweight design, and improved durability, making them ideal for various cooling applications.

2. How do Rollbond plates differ from traditional cooling methods?

Unlike traditional cooling methods, Rollbond plates utilize a unique bonding process that increases surface area for heat exchange, leading to higher efficiency and reduced energy consumption.

3. In which industries are Rollbond plates commonly used?

Rollbond plates are widely utilized in industrial refrigeration, air conditioning systems, and heat pump applications.

4. What challenges are associated with the manufacturing of Rollbond plates?

Manufacturing challenges include maintaining the integrity of the bonding process and ensuring uniformity in the bonded channels.

5. What future trends should we expect in Rollbond technology?

Future trends may include the use of emerging materials, improved manufacturing techniques, and a focus on sustainability in design.

This comprehensive exploration of Rollbond plates in cooling systems highlights not only their innovative designs but also their significant advantages in modern applications, positioning them as a critical component in the evolution of cooling technology.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.