Exploring the Benefits of Rollbond Aluminum Plates in Industrial Equipment

Exploring the Benefits of Rollbond Aluminum Plates in Industrial Equipment Table of Contents 1. Introduction to Rollbond Aluminum Plates 2. What Are Rollbond Aluminum Plates? 3. Advantages of Rollbond Aluminum Plates in Industrial Applications 3.1 Durability and Longevity 3.2 Superior Thermal Conductivity 3.3 Weight Efficiency 3

Published:

2026-01-07

source:

author:

Exploring the Benefits of Rollbond Aluminum Plates in Industrial Equipment

Table of Contents

- 1. Introduction to Rollbond Aluminum Plates

- 2. What Are Rollbond Aluminum Plates?

- 3. Advantages of Rollbond Aluminum Plates in Industrial Applications

- 3.1 Durability and Longevity

- 3.2 Superior Thermal Conductivity

- 3.3 Weight Efficiency

- 3.4 Cost-Effectiveness

- 4. Applications of Rollbond Aluminum Plates in Various Industries

- 5. The Manufacturing Process of Rollbond Aluminum Plates

- 6. Comparison with Traditional Materials

- 7. The Future of Rollbond Aluminum Plates in Industrial Equipment

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Rollbond Aluminum Plates

In the ever-evolving landscape of industrial equipment, **Rollbond aluminum plates** have emerged as a revolutionary solution that offers a myriad of benefits for manufacturers and engineers alike. Their unique properties, including lightweight design and advanced thermal efficiency, make them increasingly popular in various applications. In this article, we will delve into the attributes, advantages, manufacturing processes, and future prospects of Rollbond aluminum plates in industrial settings.

2. What Are Rollbond Aluminum Plates?

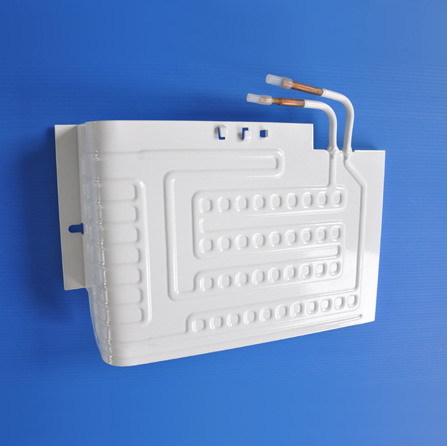

Rollbond aluminum plates consist of two thin layers of aluminum that are bonded together through a specialized process of rolling and heating. This innovative technique creates a composite material that significantly enhances the thermal conductivity and mechanical properties of aluminum. The resulting plates are incredibly thin yet possess remarkable strength and versatility, making them ideal for use in demanding industrial environments.

3. Advantages of Rollbond Aluminum Plates in Industrial Applications

Understanding the benefits of Rollbond aluminum plates is essential for industries looking to optimize their processes.

3.1 Durability and Longevity

One of the standout features of Rollbond aluminum plates is their **durability**. The bonding process not only enhances the structural integrity of the material but also makes it resistant to wear and tear. This resilience leads to a longer lifespan compared to traditional aluminum plates, reducing the need for frequent replacements and maintenance.

3.2 Superior Thermal Conductivity

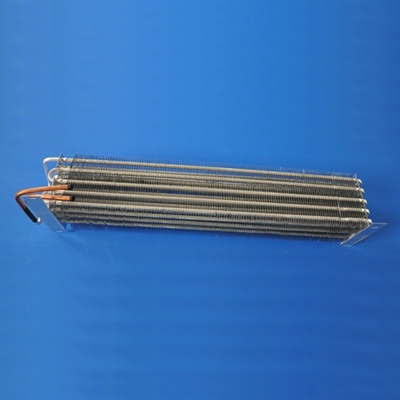

Rollbond aluminum plates excel in **thermal conductivity**, a critical factor in applications such as heat exchangers. The enhanced surface area created by the bonding process allows for efficient heat transfer, making them an ideal choice for industries that prioritize energy efficiency. This characteristic is particularly beneficial in environments where temperature control is paramount.

3.3 Weight Efficiency

The lightweight nature of Rollbond aluminum plates presents a significant advantage in various industrial applications. Their reduced weight leads to improved **energy efficiency** during transportation and installation. In sectors such as aerospace and automotive, where weight reduction directly correlates with performance, Rollbond aluminum plates prove invaluable.

3.4 Cost-Effectiveness

While the initial investment in Rollbond aluminum plates may be higher than that of traditional materials, their long-term cost-effectiveness is undeniable. Their durability and efficiency lead to reduced operational costs over time. Furthermore, the energy savings from enhanced thermal conductivity can offset the initial expenditure, making them a wise investment for businesses.

4. Applications of Rollbond Aluminum Plates in Various Industries

Rollbond aluminum plates are versatile and find applications across multiple industries.

4.1 Heat Exchangers

In the field of **heat exchangers**, Rollbond aluminum plates are essential due to their superior thermal management capabilities. Their design allows for maximum heat transfer efficiency, optimizing the performance of cooling and heating systems in industrial processes.

4.2 Aerospace Components

The **aerospace industry** is another sector where Rollbond aluminum plates shine. Their lightweight and strong properties make them suitable for various components, contributing to overall weight savings in aircraft design and enhancing fuel efficiency.

4.3 Automotive Manufacturing

In automotive manufacturing, the demand for lightweight materials is ever-increasing. Rollbond aluminum plates facilitate the production of more efficient vehicles by reducing weight while maintaining strength and safety standards. This shift towards lightweight materials aligns with the industry's goal of producing eco-friendly vehicles.

5. The Manufacturing Process of Rollbond Aluminum Plates

The manufacturing process of Rollbond aluminum plates involves several key steps that ensure high quality and performance. Initially, two layers of aluminum foil are carefully selected and prepared. These layers are then subjected to a rolling process, where they are pressed together under extreme pressure. Following this, the plates undergo a heat treatment process that activates the bonding mechanism, resulting in a strong, durable composite material.

This intricate manufacturing process is crucial in producing Rollbond aluminum plates that meet the stringent requirements of industrial applications. Each step is designed to optimize the material's properties, ensuring that they stand up to the demands of various environments.

6. Comparison with Traditional Materials

When comparing Rollbond aluminum plates to traditional materials like stainless steel or regular aluminum, several key differences emerge. Traditional materials often lack the superior thermal conductivity and weight efficiency offered by Rollbond aluminum plates. Furthermore, traditional materials can be more prone to corrosion and wear, resulting in higher maintenance costs over time.

Rollbond aluminum plates provide a competitive edge through their unique properties, making them a preferred choice in many industrial applications.

7. The Future of Rollbond Aluminum Plates in Industrial Equipment

As industries continue to evolve, the demand for innovative materials like Rollbond aluminum plates is expected to grow. Advancements in manufacturing processes and increasing awareness of sustainability will further propel the adoption of these plates across various sectors. Additionally, ongoing research into enhancing the properties of Rollbond aluminum plates could lead to even more applications, solidifying their position in the market.

The future of Rollbond aluminum plates is bright, as they provide solutions that align with the industry's needs for efficiency, durability, and performance.

8. Frequently Asked Questions (FAQs)

What is the primary benefit of Rollbond aluminum plates?

The primary benefit is their superior thermal conductivity and durability, making them ideal for applications requiring efficient heat transfer.

Are Rollbond aluminum plates more expensive than traditional materials?

While the initial cost may be higher, their long-term durability and cost-effectiveness make them a wise investment.

In which industries are Rollbond aluminum plates commonly used?

They are commonly used in aerospace, automotive, and HVAC industries, particularly in heat exchangers.

How do Rollbond aluminum plates compare to other materials in terms of weight?

Rollbond aluminum plates are significantly lighter than traditional materials, which contributes to better energy efficiency and performance.

Can Rollbond aluminum plates be recycled?

Yes, Rollbond aluminum plates can be recycled, contributing to their sustainability as a material choice in industrial applications.

9. Conclusion

In conclusion, Rollbond aluminum plates represent a significant advancement in industrial equipment design and manufacturing. Their unique benefits, including durability, superior thermal conductivity, weight efficiency, and cost-effectiveness, make them an excellent choice for various industries. As we continue to seek innovative solutions to enhance efficiency and sustainability in industrial applications, Rollbond aluminum plates will undoubtedly play a vital role in shaping the future of manufacturing. By investing in this advanced material, industries can not only improve their operational efficiency but also contribute to a more sustainable future.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.