Understanding Heat Exchanger Evaporators: Essential Insights for Industrial Applications

In the realm of industrial equipment, heat exchanger evaporators play a pivotal role in various thermal management applications. These devices are essential for transferring heat between two or more fluids without mixing them, thereby facilitating efficient thermal control in a wide array of processes. Understanding how heat exchanger evaporators operate is crucial for professionals seeking to opt

Published:

2025-12-17

source:

author:

In the realm of industrial equipment, heat exchanger evaporators play a pivotal role in various thermal management applications. These devices are essential for transferring heat between two or more fluids without mixing them, thereby facilitating efficient thermal control in a wide array of processes. Understanding how heat exchanger evaporators operate is crucial for professionals seeking to optimize system performance and energy efficiency.

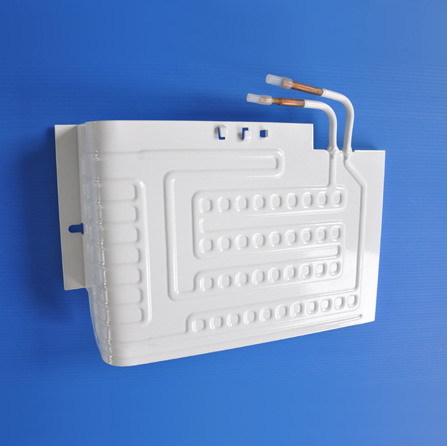

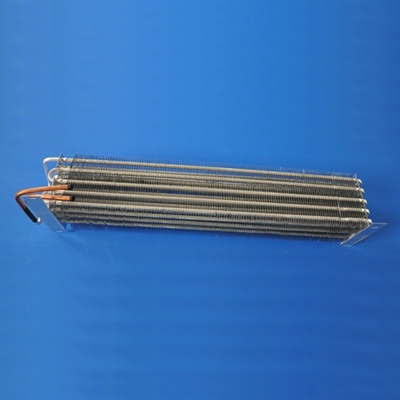

A heat exchanger evaporator primarily functions to facilitate the phase change of a refrigerant or another fluid from a liquid to a vapor. This process takes place when heat is absorbed from a secondary fluid, typically a gas or liquid, which is being cooled or conditioned. The design of an evaporator can vary significantly based on application needs, with common types including shell-and-tube, plate, and finned-tube evaporators. Each type has its unique advantages and is selected based on factors such as capacity, space constraints, and the nature of the fluids involved.

One of the critical features of a heat exchanger evaporator is its ability to enhance heat transfer efficiency through various mechanisms such as increasing surface area, optimizing flow patterns, or incorporating advanced materials. For instance, using enhanced surface designs can significantly improve heat transfer rates, making the evaporator more effective in its operation. This is particularly important in processes where maintaining specific temperature ranges is vital for product quality or operational safety.

Additionally, the selection and maintenance of heat exchanger evaporators are essential considerations in industrial operations. The choice of the evaporator must align with the overall system design, including the types of fluids used, their flow rates, and the desired thermal outcomes. Regular maintenance is also critical to ensure the longevity and reliability of the evaporator. This includes monitoring for fouling, corrosion, and leakage, all of which can adversely affect performance and energy efficiency.

Another important aspect to consider is the integration of modern technologies in heat exchanger evaporators. With advancements in control systems and sensors, it is now possible to monitor and adjust the performance of evaporators in real-time. This leads to improved energy management and operational flexibility, allowing for better responsiveness to fluctuating process demands.

In conclusion, heat exchanger evaporators are essential components in industrial thermal management systems. By understanding their operation, design variations, and maintenance requirements, professionals can significantly enhance the efficiency and reliability of their thermal processes. As industries continue to evolve, staying informed about advancements in heat transfer technologies will be crucial for optimizing performance and achieving energy sustainability goals.

A heat exchanger evaporator primarily functions to facilitate the phase change of a refrigerant or another fluid from a liquid to a vapor. This process takes place when heat is absorbed from a secondary fluid, typically a gas or liquid, which is being cooled or conditioned. The design of an evaporator can vary significantly based on application needs, with common types including shell-and-tube, plate, and finned-tube evaporators. Each type has its unique advantages and is selected based on factors such as capacity, space constraints, and the nature of the fluids involved.

One of the critical features of a heat exchanger evaporator is its ability to enhance heat transfer efficiency through various mechanisms such as increasing surface area, optimizing flow patterns, or incorporating advanced materials. For instance, using enhanced surface designs can significantly improve heat transfer rates, making the evaporator more effective in its operation. This is particularly important in processes where maintaining specific temperature ranges is vital for product quality or operational safety.

Additionally, the selection and maintenance of heat exchanger evaporators are essential considerations in industrial operations. The choice of the evaporator must align with the overall system design, including the types of fluids used, their flow rates, and the desired thermal outcomes. Regular maintenance is also critical to ensure the longevity and reliability of the evaporator. This includes monitoring for fouling, corrosion, and leakage, all of which can adversely affect performance and energy efficiency.

Another important aspect to consider is the integration of modern technologies in heat exchanger evaporators. With advancements in control systems and sensors, it is now possible to monitor and adjust the performance of evaporators in real-time. This leads to improved energy management and operational flexibility, allowing for better responsiveness to fluctuating process demands.

In conclusion, heat exchanger evaporators are essential components in industrial thermal management systems. By understanding their operation, design variations, and maintenance requirements, professionals can significantly enhance the efficiency and reliability of their thermal processes. As industries continue to evolve, staying informed about advancements in heat transfer technologies will be crucial for optimizing performance and achieving energy sustainability goals.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.