How to Choose the Right Heat Exchanger Evaporator for Your System: A Comprehensive Guide

How to Choose the Right Heat Exchanger Evaporator for Your System Table of Contents Understanding Heat Exchangers and Evaporators Types of Heat Exchangers Used in Evaporation Key Factors to Consider When Choosing an Evaporator Evaluating Performance and Efficiency Material Considerations for Heat Exchanger Evaporators Sizing and Capacity: Getting it Right Installation and Maintenanc

Published:

2025-12-10

source:

author:

How to Choose the Right Heat Exchanger Evaporator for Your System

Table of Contents

- Understanding Heat Exchangers and Evaporators

- Types of Heat Exchangers Used in Evaporation

- Key Factors to Consider When Choosing an Evaporator

- Evaluating Performance and Efficiency

- Material Considerations for Heat Exchanger Evaporators

- Sizing and Capacity: Getting it Right

- Installation and Maintenance Tips

- Common Mistakes to Avoid When Selecting Evaporators

- Frequently Asked Questions

- Conclusion

Understanding Heat Exchangers and Evaporators

In industrial applications, **heat exchangers** play a pivotal role in transferring heat between two or more fluids without mixing them. An **evaporator** specifically focuses on converting liquid into vapor by adding heat. Understanding their functionality is crucial for selecting the right system for your needs.

Heat exchangers vary in design, including shell and tube, plate, and finned-tube configurations, each serving unique purposes based on operational requirements. Knowing the differences will guide you in making an informed selection.

Types of Heat Exchangers Used in Evaporation

Selecting the appropriate heat exchanger evaporator begins with understanding the types available:

1. Shell and Tube Heat Exchangers

These consist of a series of tubes, one set carrying the hot fluid and the other the cold. They are robust and suitable for high-pressure applications, making them ideal for industrial use.

2. Plate Heat Exchangers

Featuring thin plates stacked together, this type offers a large surface area for heat transfer in a compact design. They are efficient and easy to clean, suitable for various applications, including food and beverage processing.

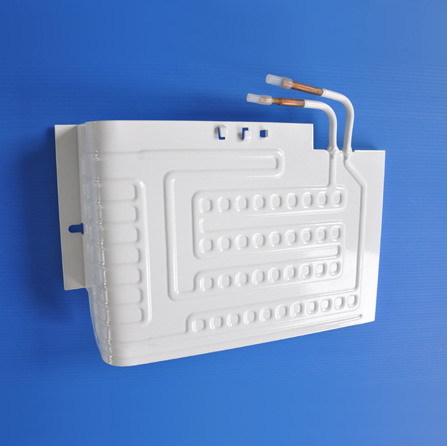

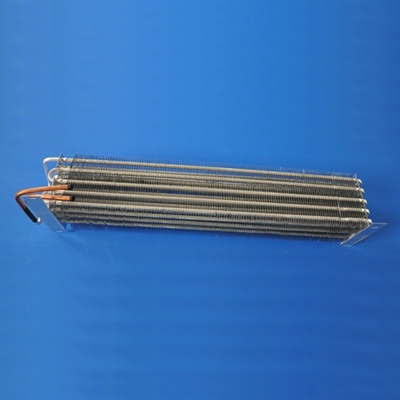

3. Finned Tube Heat Exchangers

Finned tube exchangers enhance heat transfer by increasing surface area. They are often used in air conditioning and refrigeration systems.

4. Evaporative Coolers

Though not traditional heat exchangers, evaporative coolers utilize the evaporation process to cool air, making them valuable in HVAC applications.

Key Factors to Consider When Choosing an Evaporator

When selecting a heat exchanger evaporator, consider the following critical factors:

1. Temperature and Pressure Conditions

Understanding the operational temperature and pressure is fundamental. Ensure that the heat exchanger can withstand these conditions without compromising performance.

2. Fluid Properties

Different fluids have unique properties, including viscosity, corrosiveness, and thermal conductivity. Select a heat exchanger that accommodates these properties for optimal performance.

3. Flow Rates

Determine the required flow rates for your system. The heat exchanger must efficiently handle these rates to maintain the necessary heat transfer.

4. System Integration

Evaluate how the heat exchanger will integrate into your existing system. Compatibility with other components, such as pumps and valves, is crucial for seamless operation.

Evaluating Performance and Efficiency

Performance metrics play a vital role in selecting a heat exchanger evaporator. Here are some aspects to evaluate:

1. Thermal Efficiency

Assess the thermal efficiency of the heat exchanger. A higher efficiency translates to better performance and lower operational costs.

2. Overall Heat Transfer Coefficient (U-value)

The U-value indicates how effectively heat is transferred within the system. A higher U-value signifies better heat transfer efficiency.

3. Pressure Drop

Minimize pressure drop to enhance energy efficiency. High pressure drops can lead to increased pumping costs and reduced system performance.

Material Considerations for Heat Exchanger Evaporators

The material of the heat exchanger is crucial for durability and performance. Common materials include:

1. Stainless Steel

Corrosion-resistant and strong, stainless steel is suitable for various industrial applications, especially where hygiene is a concern.

2. Carbon Steel

Cost-effective yet versatile, carbon steel is often used in less corrosive environments.

3. Copper and Alloys

Copper offers excellent thermal conductivity and is used in applications where high efficiency is required.

4. Special Alloys

For aggressive or corrosive environments, custom alloys may be necessary to ensure longevity and reliability.

Sizing and Capacity: Getting it Right

Proper sizing of your heat exchanger is critical. An undersized unit can lead to inefficiencies, while an oversized unit may incur unnecessary costs.

1. Calculating Heat Load

Determine the total heat load required for your system. This calculation involves considering the inlet and outlet temperatures, fluid types, and flow rates.

2. Selecting the Right Evaporator Size

Once the heat load is understood, select an evaporator size that meets this requirement while allowing for potential future expansion.

Installation and Maintenance Tips

Proper installation and regular maintenance are essential for the longevity and efficiency of your heat exchanger evaporator.

1. Professional Installation

Always engage professional services for installation to ensure compliance with industry standards and optimal performance.

2. Regular Maintenance Checks

Implement a maintenance schedule to inspect for leaks, corrosion, and efficiency levels. Regular cleaning is also essential to maintain performance.

3. Monitoring System Performance

Utilize monitoring tools to track the performance of your heat exchanger actively. Early detection of issues can prevent costly downtime.

Common Mistakes to Avoid When Selecting Evaporators

Avoiding common pitfalls can ensure a successful selection process:

1. Ignoring Fluid Properties

Always consider the properties of the fluids involved. Ignoring these can lead to material compatibility issues and reduced efficiency.

2. Underestimating Maintenance Needs

Neglecting maintenance requirements can lead to premature failure and operational inefficiencies.

3. Choosing Based on Cost Alone

While budget is important, selecting a heat exchanger based solely on cost can lead to poor performance and increased operational costs in the long run.

Frequently Asked Questions

1. What is the primary function of a heat exchanger evaporator?

The primary function of a heat exchanger evaporator is to transfer heat from one fluid to another, facilitating the process of converting liquid into vapor.

2. How do I determine the right size for my heat exchanger?

To determine the right size, calculate the required heat load based on the operating conditions, including inlet/outlet temperatures and flow rates.

3. Can I use any material for my heat exchanger evaporator?

No, the material must be compatible with the fluids being processed and should withstand the operational conditions (temperature, pressure, and corrosion).

4. How often should I perform maintenance on my heat exchanger?

Regular maintenance should be performed at least annually, with more frequent checks in critical applications to ensure optimal performance.

5. What are the signs that my heat exchanger needs replacement?

Signs include significant drops in performance, frequent leaks, corrosion, and increased energy costs associated with operation.

Conclusion

Choosing the right heat exchanger evaporator is a decision that impacts the efficiency and effectiveness of your industrial processes. By understanding the various types, performance metrics, and material considerations, along with avoiding common pitfalls, you can select an evaporator that meets your specific needs. Prioritize regular maintenance and professional installation to ensure longevity and optimal performance in your operations. With the right knowledge and tools, you can enhance your system's efficiency and reliability, leading to greater overall success in your industrial endeavors.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.