Understanding Heat Exchanger Evaporators: Essential Components in Industrial Systems

Heat exchanger evaporators are essential components in various industrial processes, playing a crucial role in thermal management. These devices are designed to transfer heat between two fluids—typically one being a refrigerant and the other being a process fluid—while maintaining their physical separation. The primary function of an evaporator is to absorb heat from the surrounding environment, c

Published:

2025-12-03

source:

author:

Heat exchanger evaporators are essential components in various industrial processes, playing a crucial role in thermal management. These devices are designed to transfer heat between two fluids—typically one being a refrigerant and the other being a process fluid—while maintaining their physical separation. The primary function of an evaporator is to absorb heat from the surrounding environment, causing the refrigerant within to evaporate and transition from liquid to gas. This process not only regulates temperature but also enables efficient cooling and heating in numerous applications.

One of the most significant advantages of employing a heat exchanger evaporator is its ability to optimize energy usage. By efficiently transferring heat, these devices help reduce energy consumption and lower operational costs. Furthermore, they improve system reliability by maintaining stable temperatures, which is essential for protecting sensitive equipment and processes.

Understanding the operational principles of heat exchanger evaporators can help identify their appropriate applications. Evaporators are commonly used in refrigeration systems, air conditioning units, and various industrial processes such as chemical manufacturing, food processing, and HVAC systems. In these applications, the evaporator absorbs heat from the fluid to be cooled, which reduces the temperature of the process fluid, while the refrigerant evaporates, leaving the system ready for further cooling cycles.

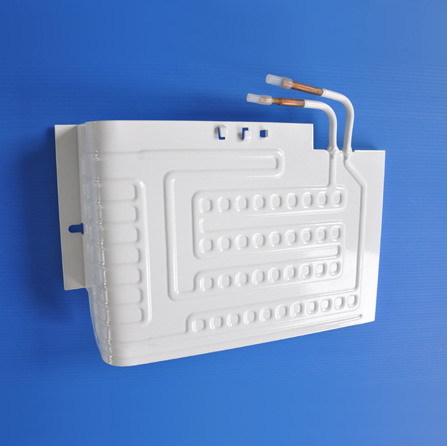

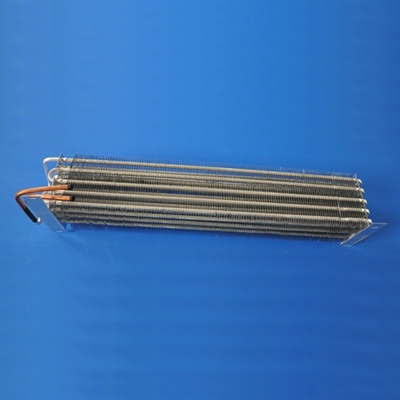

Moreover, heat exchanger evaporators come in various designs, including shell-and-tube, plate, and finned-tube configurations. Each design has its unique advantages and is suitable for specific applications. For instance, shell-and-tube evaporators are commonly used in larger industrial systems due to their durability and efficiency in handling high-pressure fluids. In contrast, plate evaporators offer a compact design and high heat transfer rates, making them ideal for applications with limited space.

In summary, heat exchanger evaporators are vital components in the realm of industrial equipment and thermal management. Their ability to transfer heat efficiently not only enhances energy efficiency but also ensures the smooth operation of various systems. Understanding their functions, designs, and applications can greatly benefit industries looking to optimize their thermal processes and overall performance. By leveraging these insights, businesses can make informed decisions regarding the selection and implementation of heat exchanger evaporators, ultimately contributing to their operational success and sustainability.

One of the most significant advantages of employing a heat exchanger evaporator is its ability to optimize energy usage. By efficiently transferring heat, these devices help reduce energy consumption and lower operational costs. Furthermore, they improve system reliability by maintaining stable temperatures, which is essential for protecting sensitive equipment and processes.

Understanding the operational principles of heat exchanger evaporators can help identify their appropriate applications. Evaporators are commonly used in refrigeration systems, air conditioning units, and various industrial processes such as chemical manufacturing, food processing, and HVAC systems. In these applications, the evaporator absorbs heat from the fluid to be cooled, which reduces the temperature of the process fluid, while the refrigerant evaporates, leaving the system ready for further cooling cycles.

Moreover, heat exchanger evaporators come in various designs, including shell-and-tube, plate, and finned-tube configurations. Each design has its unique advantages and is suitable for specific applications. For instance, shell-and-tube evaporators are commonly used in larger industrial systems due to their durability and efficiency in handling high-pressure fluids. In contrast, plate evaporators offer a compact design and high heat transfer rates, making them ideal for applications with limited space.

In summary, heat exchanger evaporators are vital components in the realm of industrial equipment and thermal management. Their ability to transfer heat efficiently not only enhances energy efficiency but also ensures the smooth operation of various systems. Understanding their functions, designs, and applications can greatly benefit industries looking to optimize their thermal processes and overall performance. By leveraging these insights, businesses can make informed decisions regarding the selection and implementation of heat exchanger evaporators, ultimately contributing to their operational success and sustainability.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.