Exploring the Compatibility of Aluminum Tube Evaporators with Modern Coolants

Exploring the Compatibility of Aluminum Tube Evaporators with Modern Coolants In the ever-evolving landscape of industrial refrigeration and cooling systems, the materials and technologies employed play a pivotal role in determining performance and efficiency. One area of growing interest is the compatibility of aluminum tube evaporators with modern coolants. As industries seek more effective cool

Published:

2025-11-12

source:

author:

Exploring the Compatibility of Aluminum Tube Evaporators with Modern Coolants

In the ever-evolving landscape of industrial refrigeration and cooling systems, the materials and technologies employed play a pivotal role in determining performance and efficiency. One area of growing interest is the compatibility of aluminum tube evaporators with modern coolants. As industries seek more effective cooling solutions, understanding this compatibility becomes crucial for engineers and manufacturers alike. In this detailed exploration, we will cover the composition of aluminum evaporators, the types of coolants available, and the implications for system performance.

Table of Contents

- 1. Introduction to Aluminum Tube Evaporators

- 2. Understanding Modern Coolants

- 3. Benefits of Using Aluminum Tube Evaporators

- 4. Compatibility Factors Between Aluminum and Coolants

- 5. Evaluating Corrosion Resistance

- 6. Thermal Conductivity and Efficiency

- 7. Industry Best Practices for Selection

- 8. FAQs About Aluminum Evaporators and Coolants

- 9. Conclusion

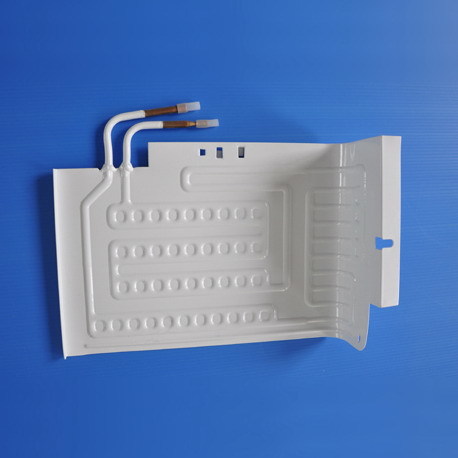

1. Introduction to Aluminum Tube Evaporators

Aluminum tube evaporators are increasingly used in various applications due to their lightweight nature and excellent heat transfer capabilities. The primary function of these evaporators is to absorb heat from the surrounding environment, enabling efficient cooling in systems such as air conditioning units, refrigeration systems, and industrial chillers. Understanding the design and operation of aluminum tube evaporators is fundamental for professionals working in HVAC and refrigeration fields.

1.1 The Role of Aluminum in Evaporator Design

Aluminum is favored for its high thermal conductivity, which enhances the efficiency of heat exchange. Furthermore, its ability to form a protective oxide layer prevents corrosion and extends the lifespan of evaporators. These properties make aluminum a prime candidate for modern cooling applications.

2. Understanding Modern Coolants

Modern coolants have evolved significantly, driven by the need for more efficient and environmentally friendly options. Traditional refrigerants are gradually being replaced by alternatives that offer lower global warming potential and improved thermal properties. Common examples include hydrofluoroolefins (HFOs), ammonia (NH3), and carbon dioxide (CO2).

2.1 Types of Modern Coolants

- Hydrofluorocarbons (HFCs): Widely used but facing phase-out due to environmental concerns.

- Hydrofluoroolefins (HFOs): Newer alternatives with lower GWP and similar performance to HFCs.

- Ammonia (NH3): Highly efficient but requires careful handling due to toxicity.

- Carbon Dioxide (CO2): Environmentally friendly, suitable for low-temperature applications.

3. Benefits of Using Aluminum Tube Evaporators

The use of aluminum tube evaporators offers several advantages in various applications:

3.1 Lightweight and Cost-Effective

Aluminum is lighter than other metals, making it easier to transport and install. Additionally, its cost-effectiveness compared to copper and stainless steel allows manufacturers to save on production costs while maintaining performance.

3.2 Superior Heat Transfer Properties

Aluminum's thermal conductivity ensures efficient heat transfer, which is essential for achieving optimal cooling performance in refrigeration systems.

4. Compatibility Factors Between Aluminum and Coolants

Compatibility between aluminum tube evaporators and modern coolants is influenced by several factors, including chemical composition, temperature range, and operating pressure. Assessing these compatibility factors is vital to prevent system failures and ensure longevity.

4.1 Chemical Compatibility

The interaction between aluminum and various coolants can lead to corrosion or degradation of the evaporator material. It is essential to evaluate the chemical properties of coolants, especially when introducing new refrigerants into existing systems.

4.2 Temperature and Pressure Considerations

Modern cooling systems often operate at higher pressures and temperatures. Therefore, the selected coolant must be compatible with aluminum under these conditions to ensure safe and efficient operation.

5. Evaluating Corrosion Resistance

Corrosion is a significant concern for aluminum tube evaporators, particularly when exposed to aggressive coolants. Conducting tests to evaluate corrosion resistance is crucial when selecting a coolant.

5.1 Types of Corrosion

- Pitting Corrosion: Localized corrosion that leads to the formation of small pits in the aluminum.

- Galvanic Corrosion: Occurs when aluminum is in contact with a more noble metal in the presence of an electrolyte.

- Uniform Corrosion: General corrosion that affects the entire surface of the aluminum.

5.2 Testing Methods for Corrosion Resistance

Corrosion testing methods, such as immersion tests and electrochemical impedance spectroscopy, can help determine the longevity of aluminum evaporators when in contact with various coolants.

6. Thermal Conductivity and Efficiency

Thermal efficiency is crucial for the performance of any cooling system. The interaction between aluminum and modern coolants significantly impacts thermal conductivity and overall efficiency.

6.1 Analyzing Thermal Performance

Conducting thermal performance evaluations helps identify the most effective combinations of aluminum evaporators and coolants. Factors like flow rate, temperature differential, and pressure drops should be assessed to ensure optimal performance.

7. Industry Best Practices for Selection

Choosing the right aluminum tube evaporator and compatible coolant requires adherence to industry best practices. Here are some guidelines:

7.1 Compatibility Testing

Before deploying new coolants in existing systems, conducting compatibility tests with aluminum components is vital. This helps prevent unforeseen issues and ensures system reliability.

7.2 Regular Maintenance

Implementing a regular maintenance schedule allows for the early detection of potential issues, such as corrosion or leaks, ensuring the longevity of both the evaporator and the coolant.

8. FAQs About Aluminum Evaporators and Coolants

8.1 What are the main advantages of aluminum tube evaporators?

Aluminum tube evaporators are lightweight, cost-effective, and offer superior thermal conductivity, making them ideal for various cooling applications.

8.2 Are all modern coolants compatible with aluminum?

No, not all coolants are compatible with aluminum. It is essential to evaluate the chemical properties of each coolant to ensure compatibility.

8.3 How can I test for corrosion resistance in my evaporator?

Corrosion resistance can be tested through various methods, including immersion tests and electrochemical impedance spectroscopy.

8.4 What maintenance practices should be implemented for aluminum evaporators?

A regular maintenance schedule should include inspections for corrosion, leaks, and overall system performance to ensure longevity and efficiency.

8.5 Can I replace traditional refrigerants with modern coolants in my existing system?

Yes, but it is crucial to conduct compatibility tests before making any changes to ensure the new coolant will not adversely affect the aluminum components.

9. Conclusion

In conclusion, understanding the compatibility of aluminum tube evaporators with modern coolants is essential for optimizing system performance and reliability. By considering factors such as chemical compatibility, thermal efficiency, and corrosion resistance, industry professionals can make informed decisions that enhance the longevity and efficiency of their cooling systems. Continuous assessment and adherence to best practices will ensure that aluminum evaporators remain a valuable asset in the ever-evolving landscape of industrial refrigeration.

Hot News

Mobile website

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.