Adapting Aluminum Tube Evaporators for Emerging Industrial Technologies

Adapting Aluminum Tube Evaporators for Emerging Industrial Technologies Table of Contents 1. Introduction to Aluminum Tube Evaporators 1.1 What are Aluminum Tube Evaporators? 1.2 Importance in Industrial Applications 2. Key Advantages of Aluminum Tube Evaporators 2.1 Lightweight and Durable Construction 2.2 Enhanced Thermal Conductivity 2.3 Cost-Effectiveness in Manufacturing 3. Applications of Al

Published:

2025-10-29

source:

author:

Adapting Aluminum Tube Evaporators for Emerging Industrial Technologies

Table of Contents

1. Introduction to Aluminum Tube Evaporators

1.1 What are Aluminum Tube Evaporators?

1.2 Importance in Industrial Applications

2. Key Advantages of Aluminum Tube Evaporators

2.1 Lightweight and Durable Construction

2.2 Enhanced Thermal Conductivity

2.3 Cost-Effectiveness in Manufacturing

3. Applications of Aluminum Tube Evaporators in Emerging Technologies

3.1 Refrigeration and Air Conditioning Systems

3.2 Chemical Processing Industries

3.3 Renewable Energy Solutions

4. Innovations Driving the Adaptation of Aluminum Tube Evaporators

4.1 Advances in Manufacturing Techniques

4.2 Integration with IoT and Smart Technologies

5. Challenges and Considerations

5.1 Corrosion Resistance

5.2 Environmental Regulations

6. Conclusion

7. Frequently Asked Questions (FAQs)

1. Introduction to Aluminum Tube Evaporators

1.1 What are Aluminum Tube Evaporators?

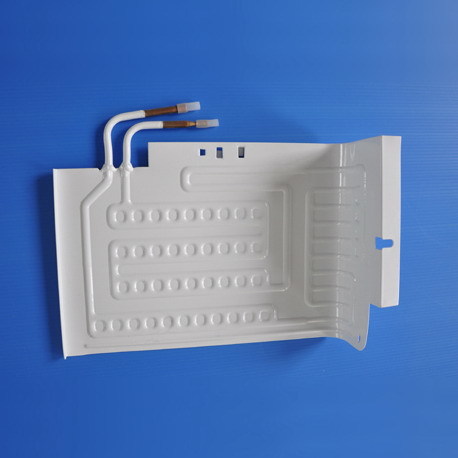

Aluminum tube evaporators are essential heat exchange devices that utilize aluminum tubing for effective thermal transfer. These systems are designed to absorb heat from a fluid and dissipate it, usually transforming a liquid into vapor in the process. Commonly used in various industrial applications, they leverage the excellent thermal properties of aluminum to achieve efficient heat management.

1.2 Importance in Industrial Applications

With the rise of advanced industrial technologies, aluminum tube evaporators are becoming increasingly vital. Their ability to adapt to various processes makes them a preferred choice in manufacturing sectors like refrigeration, chemical processing, and even renewable energy. By enhancing heat exchange efficiency, these evaporators play a crucial role in improving overall system performance.

2. Key Advantages of Aluminum Tube Evaporators

2.1 Lightweight and Durable Construction

One significant advantage of aluminum tube evaporators is their lightweight nature. This characteristic allows for easier installation and reduces the structural demands on supporting frameworks. Moreover, aluminum's inherent durability ensures a long lifespan, making these evaporators a reliable choice for industrial applications.

2.2 Enhanced Thermal Conductivity

Aluminum boasts superior thermal conductivity compared to other materials, such as copper or stainless steel. This property enables aluminum tube evaporators to transfer heat more efficiently, resulting in faster cooling and heating cycles. Industries benefit from reduced energy consumption and increased operational efficiency as a result.

2.3 Cost-Effectiveness in Manufacturing

The use of aluminum in evaporators offers significant cost savings. The material itself is generally less expensive than alternatives, and its lightweight nature can lead to lower transportation and installation costs. Additionally, the energy efficiency gained through using these evaporators can further reduce operational expenses.

3. Applications of Aluminum Tube Evaporators in Emerging Technologies

3.1 Refrigeration and Air Conditioning Systems

Aluminum tube evaporators are extensively employed in refrigeration and air conditioning systems due to their high efficiency and reliability. They facilitate effective temperature control in residential, commercial, and industrial settings.

3.2 Chemical Processing Industries

In chemical processing, these evaporators play a crucial role in various applications, including distillation, crystallization, and solvent recovery. Their efficient heat transfer capabilities are essential for maintaining precise temperatures during chemical reactions.

3.3 Renewable Energy Solutions

With the growing emphasis on sustainability, aluminum tube evaporators are increasingly found in renewable energy solutions, such as solar thermal systems. Their adaptability and efficiency make them ideal for capturing and utilizing heat from renewable sources.

4. Innovations Driving the Adaptation of Aluminum Tube Evaporators

4.1 Advances in Manufacturing Techniques

Recent advancements in manufacturing techniques, such as improved extrusion processes and enhanced joining methods, have significantly increased the performance and reliability of aluminum tube evaporators. These innovations enable manufacturers to produce more efficient and durable products tailored to specific industrial needs.

4.2 Integration with IoT and Smart Technologies

The integration of Internet of Things (IoT) technology into aluminum tube evaporators is revolutionizing their operation. Smart sensors can monitor temperature and pressure in real-time, allowing for optimized performance and predictive maintenance, which ultimately reduces downtime and operational costs.

5. Challenges and Considerations

5.1 Corrosion Resistance

While aluminum is a strong material, it is susceptible to corrosion. In industrial environments, this can pose a challenge. Protective coatings and alloy formulations are essential in ensuring the longevity and reliability of aluminum tube evaporators in corrosive environments.

5.2 Environmental Regulations

As industries face increasing environmental regulations, the need for aluminum tube evaporators that comply with these standards is crucial. Manufacturers must focus on developing systems that not only perform well but also meet regulatory requirements related to emissions and energy consumption.

6. Conclusion

The adaptation of aluminum tube evaporators in emerging industrial technologies highlights the critical role they play in enhancing efficiency and sustainability across various sectors. Their lightweight design, superior thermal conductivity, and cost-effectiveness make them a preferred choice in modern manufacturing processes. As advancements in technology continue to unfold, the importance of these essential components will only grow, driving innovation and improvement in industrial applications.

7. Frequently Asked Questions (FAQs)

1. What are the primary benefits of using aluminum tube evaporators in industrial applications?

Aluminum tube evaporators offer several benefits, including lightweight construction, enhanced thermal conductivity, and cost-effectiveness, making them ideal for various industrial uses.

2. How do aluminum tube evaporators compare to other materials?

Compared to materials like copper or stainless steel, aluminum provides superior thermal conductivity and is generally more cost-effective, though it may require additional corrosion protection.

3. What industries benefit most from aluminum tube evaporators?

Industries such as refrigeration, air conditioning, chemical processing, and renewable energy heavily rely on aluminum tube evaporators for efficient heat transfer solutions.

4. What innovations are influencing the future of aluminum tube evaporators?

Advancements in manufacturing techniques and the integration of IoT technologies are shaping the future of aluminum tube evaporators, allowing for smarter and more efficient operation.

5. Are there any environmental concerns associated with aluminum tube evaporators?

While aluminum is generally recyclable and has a lower environmental impact than many alternatives, issues such as corrosion and compliance with environmental regulations must be addressed during its use in industrial applications.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.