How Aluminum Plate Evaporators Enhance Heat Transfer Efficiency

How Aluminum Plate Evaporators Enhance Heat Transfer Efficiency Table of Contents 1. Introduction to Aluminum Plate Evaporators 2. The Science Behind Heat Transfer 3. Advantages of Using Aluminum Plate Evaporators 3.1. Improved Thermal Conductivity 3.2. Compact Design and Space Efficiency 3.3. Enhanced Durability and Corrosion Resistance 3.4. Energy Efficiency and Cost Savings 4. Applications of A

Published:

2025-10-15

source:

author:

How Aluminum Plate Evaporators Enhance Heat Transfer Efficiency

Table of Contents

1. Introduction to Aluminum Plate Evaporators

2. The Science Behind Heat Transfer

3. Advantages of Using Aluminum Plate Evaporators

3.1. Improved Thermal Conductivity

3.2. Compact Design and Space Efficiency

3.3. Enhanced Durability and Corrosion Resistance

3.4. Energy Efficiency and Cost Savings

4. Applications of Aluminum Plate Evaporators

4.1. Refrigeration and Air Conditioning

4.2. Chemical Processing

4.3. Food and Beverage Industry

5. Operational Considerations for Aluminum Plate Evaporators

5.1. Maintenance Best Practices

5.2. Selecting the Right Evaporator Size

6. Conclusion

7. Frequently Asked Questions (FAQs)

1. Introduction to Aluminum Plate Evaporators

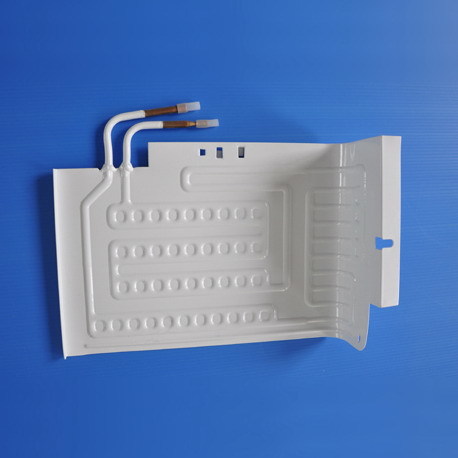

Aluminum plate evaporators represent a significant advancement in thermal management technology. These components are integral in various industries where precise temperature control is crucial. Unlike traditional evaporators, aluminum plate evaporators utilize a unique design that significantly enhances heat transfer efficiency. This article explores how these innovative devices function, their advantages, and their diverse applications.

2. The Science Behind Heat Transfer

Understanding the principles of heat transfer is essential to appreciate the innovations presented by aluminum plate evaporators. Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation. In the context of evaporators, conduction and convection are particularly relevant.

Conduction is the transfer of heat through materials, while convection involves the movement of fluids that carry heat away. Aluminum plate evaporators maximize both processes, resulting in superior thermal performance.

3. Advantages of Using Aluminum Plate Evaporators

Aluminum plate evaporators offer multiple advantages that enhance their effectiveness in various applications.

3.1. Improved Thermal Conductivity

Aluminum is known for its excellent thermal conductivity, which allows for quicker and more efficient heat transfer. This property ensures that the evaporator can perform optimally, reducing the time needed to achieve desired temperatures.

3.2. Compact Design and Space Efficiency

The design of aluminum plate evaporators is inherently compact, making them ideal for environments with limited space. Their slim profiles allow for easy integration into existing systems without requiring extensive modifications.

3.3. Enhanced Durability and Corrosion Resistance

Aluminum naturally resists corrosion, which is crucial in environments where moisture and chemicals are present. This durability extends the lifespan of the evaporator, reducing the need for frequent replacements and maintenance.

3.4. Energy Efficiency and Cost Savings

By improving heat transfer efficiency, aluminum plate evaporators can lead to significant energy savings. Reduced energy consumption not only lowers operational costs but also contributes to a more sustainable environment, making them an excellent choice for eco-conscious businesses.

4. Applications of Aluminum Plate Evaporators

Aluminum plate evaporators are versatile components used across multiple industries.

4.1. Refrigeration and Air Conditioning

In refrigeration and air conditioning systems, aluminum plate evaporators are crucial for maintaining low temperatures and ensuring optimal performance. Their efficiency helps reduce energy consumption and enhances cooling capabilities.

4.2. Chemical Processing

In chemical processing, precise temperature control is vital. Aluminum plate evaporators facilitate efficient heat exchange, ensuring that reactions occur at the desired rates and temperatures, thereby optimizing production processes.

4.3. Food and Beverage Industry

In the food and beverage sector, maintaining the right temperatures is essential for safety and quality. Aluminum plate evaporators help achieve the necessary cooling while minimizing energy consumption, making them indispensable in this industry.

5. Operational Considerations for Aluminum Plate Evaporators

While aluminum plate evaporators are highly efficient, certain operational considerations must be addressed to ensure optimal performance.

5.1. Maintenance Best Practices

Regular maintenance is key to maximizing the lifespan and efficiency of aluminum plate evaporators. This includes routine inspections, cleaning, and prompt repairs of any leaks or damages. Ensuring that the evaporator operates within its designated parameters can prevent unnecessary wear and prolong its service life.

5.2. Selecting the Right Evaporator Size

Choosing the appropriate size of an aluminum plate evaporator is crucial for achieving optimal performance. An evaporator that is too small may struggle to meet demand, while one that is too large can lead to inefficiencies and increased costs. It is vital to conduct a thorough analysis of your system's requirements before making a selection.

6. Conclusion

In conclusion, aluminum plate evaporators significantly enhance heat transfer efficiency across various industries thanks to their superior thermal conductivity, compact design, durability, and energy-saving capabilities. Understanding their advantages and applications can aid in making informed decisions for industrial processes. By incorporating aluminum plate evaporators into your systems, you can improve operational efficiency, reduce costs, and contribute to a more sustainable future.

7. Frequently Asked Questions (FAQs)

What is an aluminum plate evaporator?

An aluminum plate evaporator is a thermal management component that enhances heat transfer efficiency by utilizing aluminum's superior thermal conductivity in a compact design.

How does an aluminum plate evaporator differ from traditional evaporators?

Unlike traditional evaporators, aluminum plate evaporators utilize plates to maximize surface area for heat transfer, resulting in improved efficiency and reduced energy consumption.

What industries benefit from aluminum plate evaporators?

Aluminum plate evaporators are used in various industries, including refrigeration, chemical processing, and food and beverage production, where efficient heat transfer is crucial.

How do I maintain an aluminum plate evaporator?

Regular maintenance involves routine inspections, cleaning to prevent buildup, and immediate repairs of any leaks to ensure optimal performance and longevity.

Why is energy efficiency important for aluminum plate evaporators?

Energy efficiency reduces operational costs and environmental impact, making aluminum plate evaporators not only economically beneficial but also a sustainable choice for businesses.

This comprehensive exploration of aluminum plate evaporators and their efficiency provides a clear insight into their importance in modern industrial applications. By leveraging these innovative devices, industries can enhance their thermal management systems significantly.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.