Understanding Aluminum Plate Evaporators: Key Insights for Industrial Applications

Aluminum plate evaporators have gained prominence in industrial applications due to their superior thermal efficiency and lightweight design. These evaporators utilize aluminum plates to create a highly effective heat exchange surface, which facilitates the efficient transfer of heat in various processes. By employing a series of thin, corrugated plates, aluminum plate evaporators maximize the sur

Published:

2025-10-08

source:

author:

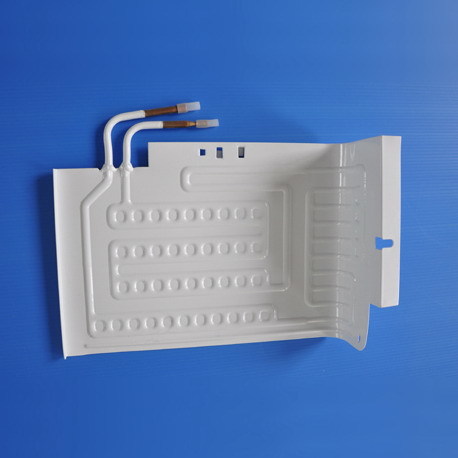

Aluminum plate evaporators have gained prominence in industrial applications due to their superior thermal efficiency and lightweight design. These evaporators utilize aluminum plates to create a highly effective heat exchange surface, which facilitates the efficient transfer of heat in various processes. By employing a series of thin, corrugated plates, aluminum plate evaporators maximize the surface area available for heat transfer, resulting in enhanced performance compared to traditional evaporators.

One of the primary advantages of aluminum plate evaporators is their ability to operate effectively in a variety of temperatures and pressures. This flexibility makes them suitable for numerous industrial applications, including refrigeration, air conditioning, and process cooling. The lightweight nature of aluminum also contributes to reduced installation and transportation costs, making these evaporators an attractive option for companies looking to optimize their operations.

Another significant aspect of aluminum plate evaporators is their corrosion resistance. Aluminum is inherently resistant to corrosion, which is critical in applications involving moist or aggressive environments. This characteristic extends the lifespan of the evaporator and reduces the need for frequent maintenance, ultimately leading to cost savings for businesses.

The design of aluminum plate evaporators also allows for easy cleaning and maintenance. The plates can often be disassembled without specialized tools, enabling quick access to the internal surfaces. This feature is particularly beneficial in industries where hygiene is paramount, such as food processing and pharmaceuticals, as it ensures that the equipment can be maintained to strict cleanliness standards.

Furthermore, the compact design of aluminum plate evaporators means they occupy less space compared to conventional evaporators. This space-saving design is advantageous for facilities with limited installation areas, allowing for more efficient use of available space without compromising performance.

In summary, aluminum plate evaporators are an efficient and versatile choice for various industrial heat exchange applications. Their lightweight construction, thermal efficiency, corrosion resistance, and ease of maintenance make them a valuable asset for businesses seeking to enhance their operational efficiency. As industries continue to evolve and demand more efficient heat exchange solutions, the role of aluminum plate evaporators is likely to become even more significant. Understanding their benefits and applications can help companies make informed decisions when selecting equipment for their specific needs.

One of the primary advantages of aluminum plate evaporators is their ability to operate effectively in a variety of temperatures and pressures. This flexibility makes them suitable for numerous industrial applications, including refrigeration, air conditioning, and process cooling. The lightweight nature of aluminum also contributes to reduced installation and transportation costs, making these evaporators an attractive option for companies looking to optimize their operations.

Another significant aspect of aluminum plate evaporators is their corrosion resistance. Aluminum is inherently resistant to corrosion, which is critical in applications involving moist or aggressive environments. This characteristic extends the lifespan of the evaporator and reduces the need for frequent maintenance, ultimately leading to cost savings for businesses.

The design of aluminum plate evaporators also allows for easy cleaning and maintenance. The plates can often be disassembled without specialized tools, enabling quick access to the internal surfaces. This feature is particularly beneficial in industries where hygiene is paramount, such as food processing and pharmaceuticals, as it ensures that the equipment can be maintained to strict cleanliness standards.

Furthermore, the compact design of aluminum plate evaporators means they occupy less space compared to conventional evaporators. This space-saving design is advantageous for facilities with limited installation areas, allowing for more efficient use of available space without compromising performance.

In summary, aluminum plate evaporators are an efficient and versatile choice for various industrial heat exchange applications. Their lightweight construction, thermal efficiency, corrosion resistance, and ease of maintenance make them a valuable asset for businesses seeking to enhance their operational efficiency. As industries continue to evolve and demand more efficient heat exchange solutions, the role of aluminum plate evaporators is likely to become even more significant. Understanding their benefits and applications can help companies make informed decisions when selecting equipment for their specific needs.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.