Top Applications for Aluminum Plate Evaporators in Industrial Settings

Top Applications for Aluminum Plate Evaporators in Industrial Settings Introduction to Aluminum Plate Evaporators Aluminum plate evaporators are at the forefront of modern industrial processes. These innovative devices play a crucial role in various sectors by efficiently transferring heat and separating components within liquids. Their unique design and material properties offer advantages over

Published:

2025-10-01

source:

author:

Top Applications for Aluminum Plate Evaporators in Industrial Settings

Introduction to Aluminum Plate Evaporators

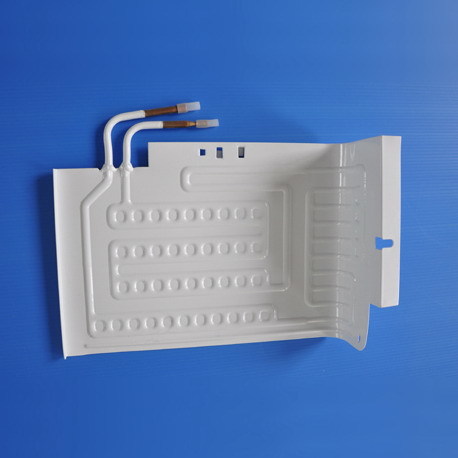

Aluminum plate evaporators are at the forefront of modern industrial processes. These innovative devices play a crucial role in various sectors by efficiently transferring heat and separating components within liquids. Their unique design and material properties offer advantages over traditional evaporators, making them an essential choice for many applications.

Understanding the Working Principle of Aluminum Plate Evaporators

To appreciate the applications of aluminum plate evaporators, it is essential to understand how they work. These evaporators utilize a series of thin aluminum plates, stacked and sealed together, to create channels for the liquid to flow. By applying heat to one side of the plates, the liquid on the opposite side reaches its boiling point, causing vapor to form. This process efficiently separates the desired components from the liquid, whether in a food, pharmaceutical, or chemical setting.

Energy Efficiency and Cost-Effectiveness

One of the primary advantages of aluminum plate evaporators is their energy efficiency. The large surface area of the plates allows for effective heat transfer, reducing energy consumption compared to traditional evaporators. This efficiency translates into significant cost savings for industries, making aluminum plate evaporators a smart investment.

Key Applications of Aluminum Plate Evaporators

With their versatility and efficiency, aluminum plate evaporators find applications across various industries. Below, we explore some of the most prominent applications.

1. Food and Beverage Industry

In the food and beverage sector, aluminum plate evaporators are primarily used for concentrating juices, dairy products, and other liquids. Their ability to preserve flavor and nutritional value during the evaporation process makes them invaluable. For example, in the dairy industry, these evaporators help concentrate milk into powder while maintaining quality.

2. Pharmaceutical Manufacturing

Aluminum plate evaporators are essential in pharmaceutical manufacturing, where precise temperature control and hygiene are paramount. They are often used to evaporate solvents from active pharmaceutical ingredients (APIs) and to concentrate solutions while ensuring that contamination risks are minimized.

3. Chemical Processing

In chemical processing, aluminum plate evaporators are employed for separating and concentrating various chemical solutions. Their ability to withstand corrosive substances and high temperatures makes them ideal for handling aggressive chemicals. This application is vital in producing fertilizers, plastics, and specialty chemicals.

4. Wastewater Treatment

Aluminum plate evaporators play a crucial role in wastewater treatment by concentrating waste streams and recovering valuable resources. The evaporation process helps reduce the volume of wastewater, making it easier to manage and treat, thus contributing to environmental sustainability.

5. Energy Sector

In the energy sector, particularly in geothermal and solar thermal applications, aluminum plate evaporators are used to recover heat from fluids. This recovered heat can then be utilized for various purposes, improving overall energy efficiency in these systems.

Benefits of Using Aluminum Plate Evaporators

The adoption of aluminum plate evaporators offers numerous benefits that enhance industrial operations.

1. Compact Design

Aluminum plate evaporators have a compact footprint, allowing for easy integration into existing systems. Their space-saving design is especially advantageous in settings where space is at a premium.

2. Durability and Corrosion Resistance

Constructed from aluminum, these evaporators exhibit excellent corrosion resistance, ensuring longevity even in harsh operating conditions. This durability translates to lower maintenance costs and reduced downtime.

3. Enhanced Heat Transfer Performance

The design of aluminum plate evaporators maximizes heat transfer efficiency. This performance is critical in applications where speed and efficiency are paramount, allowing industries to meet production demands effectively.

4. Environmentally Friendly Solutions

By optimizing energy use and reducing waste, aluminum plate evaporators contribute to more sustainable industrial practices. Their ability to recover heat and concentrate streams aligns with modern environmental goals.

Choosing the Right Aluminum Plate Evaporator

Selecting the appropriate aluminum plate evaporator for your specific application is crucial. Consider the following factors:

1. Application Requirements

Evaluate the specific needs of your application, including the type of liquid, desired concentration levels, and operational temperature ranges. This assessment will guide you in selecting an evaporator that meets your requirements.

2. Flow Rate and Capacity

Determine the required flow rate and capacity of the evaporator. Different models offer varying capacities, and choosing one that aligns with your production needs ensures optimal performance.

3. Maintenance and Support

Consider the maintenance requirements and the availability of technical support for the evaporator. A reliable support network can significantly enhance the longevity and efficiency of your equipment.

Future Trends in Aluminum Plate Evaporators

As industries evolve, so do the technologies associated with aluminum plate evaporators. Some notable trends include:

1. Integration of Smart Technologies

The incorporation of IoT and smart technologies into aluminum plate evaporators is on the rise. These advancements enable real-time monitoring and data analysis, optimizing performance and maintenance schedules.

2. Focus on Sustainability

With growing environmental concerns, future developments will likely focus on enhancing the sustainability of aluminum plate evaporators. This shift includes improving energy efficiency and minimizing waste.

3. Customization and Modularity

The demand for tailored solutions is increasing, leading manufacturers to develop modular aluminum plate evaporators. These systems allow for customization based on specific industrial needs, enhancing flexibility and efficiency.

Frequently Asked Questions (FAQs)

1. What are aluminum plate evaporators used for?

Aluminum plate evaporators are used in various applications, including food processing, pharmaceuticals, chemical manufacturing, wastewater treatment, and energy recovery.

2. How do aluminum plate evaporators compare to traditional evaporators?

Aluminum plate evaporators offer superior energy efficiency, compact design, and enhanced heat transfer performance compared to traditional evaporators.

3. What industries benefit from aluminum plate evaporators?

Industries such as food and beverage, pharmaceuticals, chemicals, and energy all benefit from the use of aluminum plate evaporators due to their efficiency and versatility.

4. Are aluminum plate evaporators environmentally friendly?

Yes, aluminum plate evaporators contribute to sustainability by optimizing energy use, reducing waste, and allowing for resource recovery in various applications.

5. How can I choose the right aluminum plate evaporator for my needs?

To choose the right evaporator, assess your application requirements, flow rate, capacity, and maintenance support options before making a decision.

Conclusion

Aluminum plate evaporators are indispensable tools in modern industrial settings, offering efficiency and versatility across multiple applications. From the food and beverage industry to chemical processing, their ability to optimize processes while being environmentally friendly makes them a preferred choice. As technology evolves, these evaporators will continue to play a significant role in enhancing industrial performance, paving the way for a sustainable and efficient future. Embracing aluminum plate evaporators is not just an investment in equipment; it's a commitment to innovation and excellence in industrial practices.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.