Why Rollbond Evaporators Are Essential for Modern Heat Transfer Applications

Introduction to Rollbond Evaporators in Heat Transfer In the ever-evolving world of industrial heat transfer applications, **Rollbond evaporators** have emerged as a pivotal technology. Their unique design and functionality not only streamline processes but also enhance energy efficiency and sustainability. In this article, we will explore why Rollbond evaporators are essential for modern heat tra

Published:

2025-05-14

source:

author:

Introduction to Rollbond Evaporators in Heat Transfer

In the ever-evolving world of industrial heat transfer applications, **Rollbond evaporators** have emerged as a pivotal technology. Their unique design and functionality not only streamline processes but also enhance energy efficiency and sustainability. In this article, we will explore why Rollbond evaporators are essential for modern heat transfer applications, detailing their advantages, applications, and future prospects.

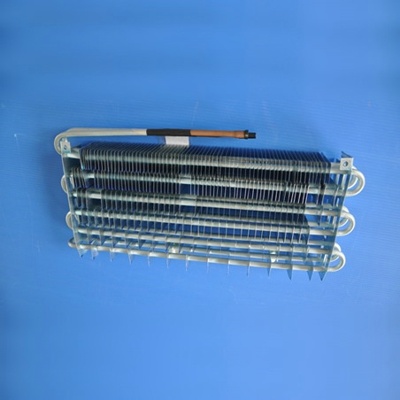

Understanding Rollbond Evaporators

Rollbond evaporators are specialized heat exchangers designed for effective vaporization of liquids. Their construction typically involves two metal sheets that are bonded together to form highly efficient heat transfer surfaces. The process of rolling and bonding results in a lightweight structure with a high surface area-to-volume ratio, which significantly enhances thermal performance.

The Unique Design Features of Rollbond Evaporators

One of the defining features of Rollbond evaporators is their ability to operate efficiently under varying thermal conditions. Key design elements include:

- **High Surface Area**: The bonded plates maximize the heat transfer area, leading to improved efficiency.

- **Compact Size**: Their lightweight and compact design make them ideal for applications where space is a constraint.

- **Durability**: Constructed from robust materials, Rollbond evaporators are designed to withstand harsh industrial environments.

How Rollbond Technology Works

Rollbond evaporators utilize a unique mechanism where liquid is passed through the bonded plates. Heat is transferred from the hot medium on one side to the liquid on the other, causing it to vaporize. This process is crucial in applications where efficient heat transfer is needed without significant pressure drop.

Advantages of Rollbond Evaporators in Heat Transfer Applications

The advantages of using Rollbond evaporators extend across various industrial sectors. Here are some of the key benefits:

1. Energy Efficiency

Energy efficiency is a critical factor in modern industrial processes. Rollbond evaporators enhance this by minimizing thermal resistance and maximizing heat transfer rates, leading to lower energy consumption and operational costs.

2. Space-Saving Design

In industries where floor space is limited, the compact design of Rollbond evaporators provides a significant advantage. Their lightweight nature allows for easy installation in confined spaces without sacrificing performance.

3. Versatility Across Industries

Rollbond evaporators are versatile and find applications in various sectors, including:

- **Food Processing**: Used for concentrating juices and dairy products.

- **Chemical Processing**: Essential in the production of specialty chemicals.

- **Pharmaceuticals**: Employed in the concentration of active ingredients.

4. Reduced Maintenance Costs

The robust design of Rollbond evaporators lowers maintenance requirements, resulting in reduced downtime and overall operating costs. Their durability ensures a longer operational life, which is a significant benefit for industrial facilities.

5. Environmental Sustainability

As industries move toward sustainable practices, Rollbond evaporators contribute by enhancing energy efficiency and reducing waste. Their design aligns with modern environmental standards, making them a responsible choice for heat transfer applications.

Applications of Rollbond Evaporators

The versatility of Rollbond evaporators makes them suitable for a wide range of applications. Below are some of the most common uses:

1. Concentration of Liquids

In processes such as fruit juice concentration, Rollbond evaporators provide efficient heat transfer, allowing for the effective removal of moisture while retaining flavor and nutrients.

2. Waste Heat Recovery

These evaporators can be integrated into systems designed to recover waste heat, making them an ideal choice for industries looking to improve energy efficiency and reduce carbon footprints.

3. Thermal Energy Storage

Rollbond evaporators play a crucial role in thermal energy storage systems, allowing industries to manage energy consumption effectively and reduce peak load demands.

4. Refrigeration and Heat Pump Systems

In refrigeration applications, Rollbond technology is employed to enhance the efficiency of heat exchangers, contributing to lower energy consumption and improved performance.

Future Trends in Rollbond Evaporator Technology

The evolution of Rollbond evaporators continues as technology advances. Some trends to watch for include:

1. Integration with IoT and Smart Technologies

The incorporation of Internet of Things (IoT) technology is transforming how industrial systems operate. Rollbond evaporators are expected to feature smart sensors and controls that optimize performance and predict maintenance needs.

2. Enhanced Materials for Improved Durability

Research into new materials will likely lead to stronger, more resilient Rollbond evaporators that can withstand extreme conditions while maintaining high efficiency.

3. Focus on Sustainable Manufacturing Practices

As sustainability becomes a priority, manufacturers are expected to adopt eco-friendly practices in producing Rollbond evaporators, ensuring that the technology aligns with industry standards for environmental responsibility.

FAQs About Rollbond Evaporators

1. What is a Rollbond evaporator?

Rollbond evaporators are specialized heat exchangers designed to efficiently vaporize liquids through a unique bonded plate technology.

2. How do Rollbond evaporators differ from traditional evaporators?

Unlike traditional evaporators, Rollbond evaporators feature a lightweight and compact design with a high surface area that enhances thermal performance and energy efficiency.

3. What industries commonly use Rollbond evaporators?

They are widely used in food processing, chemical processing, pharmaceuticals, and even waste heat recovery applications.

4. Are Rollbond evaporators environmentally friendly?

Yes, their energy-efficient design contributes to reduced operational costs and lower carbon footprints, aligning with sustainable industry practices.

5. What are the maintenance requirements for Rollbond evaporators?

Due to their robust design, Rollbond evaporators generally require less maintenance than traditional evaporators, leading to lower downtime and costs.

Conclusion

In summary, Rollbond evaporators have become indispensable in modern heat transfer applications due to their unique advantages in energy efficiency, compact design, and versatility across industries. As technology continues to evolve, we anticipate further enhancements in their design and functionality, cementing their role in sustainable industrial practices. Understanding the benefits and applications of Rollbond evaporators allows engineers and decision-makers to optimize their heat transfer processes effectively, ensuring competitiveness in a rapidly changing market. Investing in this modern heat exchange technology is not just a choice but a strategic move towards a more efficient and sustainable future.

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.