Understanding Rollbond Evaporators: A Key Component in Heat Transfer Technology

Rollbond evaporators are specialized components widely used in various industrial applications for effective heat transfer. Their unique design and operational principles make them an essential element in many cooling and heating systems. Understanding the functionality and advantages of rollbond evaporators can significantly inform their application in your projects. The rollbond evaporator gets

Published:

2025-05-21

source:

author:

Rollbond evaporators are specialized components widely used in various industrial applications for effective heat transfer. Their unique design and operational principles make them an essential element in many cooling and heating systems. Understanding the functionality and advantages of rollbond evaporators can significantly inform their application in your projects.

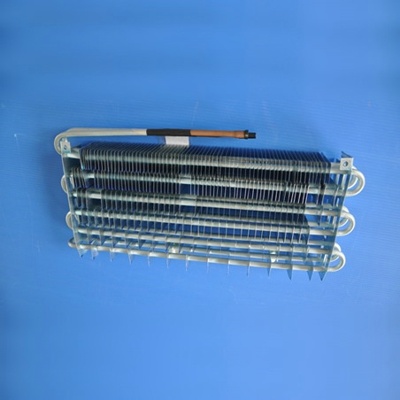

The rollbond evaporator gets its name from its manufacturing process, which involves bonding two metal plates together to form a series of channels. This creates a compact structure that maximizes the surface area available for heat exchange, thereby enhancing thermal performance. The design allows the refrigerant to flow through these channels, absorbing heat from the surrounding environment, which is then expelled elsewhere in the system.

One of the primary advantages of rollbond evaporators is their efficiency. Due to their larger surface area and optimized flow channels, they allow for improved heat transfer rates compared to traditional designs. This efficiency can lead to lower energy consumption in systems where these evaporators are employed, making them a sustainable choice for industries aiming to reduce operational costs and environmental impact.

Installation and maintenance of rollbond evaporators are generally streamlined due to their compact and lightweight nature. This makes them easier to integrate into existing systems and simplifies service access. Moreover, their robust construction ensures durability, which is crucial for maintaining performance over time, especially in demanding industrial conditions.

Another noteworthy aspect of rollbond evaporators is their versatility. They can be customized to suit various applications, including refrigeration, air conditioning, and even some chemical processes. This adaptability allows industries to implement rollbond technology in ways that best fit their operational needs.

In terms of heat transfer applications, rollbond evaporators excel in environments where space is limited but efficiency is paramount. Their design allows them to perform effectively in both high and low-temperature settings, making them suitable for a wide range of industrial processes.

In summary, rollbond evaporators represent a sophisticated solution in the realm of heat transfer technology. Their efficient design, ease of integration, and adaptability to various applications make them a valuable component for industries looking to enhance their thermal management processes. By leveraging rollbond evaporators, industries can optimize their operations, reduce energy consumption, and achieve superior heat transfer performance.

The rollbond evaporator gets its name from its manufacturing process, which involves bonding two metal plates together to form a series of channels. This creates a compact structure that maximizes the surface area available for heat exchange, thereby enhancing thermal performance. The design allows the refrigerant to flow through these channels, absorbing heat from the surrounding environment, which is then expelled elsewhere in the system.

One of the primary advantages of rollbond evaporators is their efficiency. Due to their larger surface area and optimized flow channels, they allow for improved heat transfer rates compared to traditional designs. This efficiency can lead to lower energy consumption in systems where these evaporators are employed, making them a sustainable choice for industries aiming to reduce operational costs and environmental impact.

Installation and maintenance of rollbond evaporators are generally streamlined due to their compact and lightweight nature. This makes them easier to integrate into existing systems and simplifies service access. Moreover, their robust construction ensures durability, which is crucial for maintaining performance over time, especially in demanding industrial conditions.

Another noteworthy aspect of rollbond evaporators is their versatility. They can be customized to suit various applications, including refrigeration, air conditioning, and even some chemical processes. This adaptability allows industries to implement rollbond technology in ways that best fit their operational needs.

In terms of heat transfer applications, rollbond evaporators excel in environments where space is limited but efficiency is paramount. Their design allows them to perform effectively in both high and low-temperature settings, making them suitable for a wide range of industrial processes.

In summary, rollbond evaporators represent a sophisticated solution in the realm of heat transfer technology. Their efficient design, ease of integration, and adaptability to various applications make them a valuable component for industries looking to enhance their thermal management processes. By leveraging rollbond evaporators, industries can optimize their operations, reduce energy consumption, and achieve superior heat transfer performance.

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.