Exploring the Benefits of Using Rollbond Evaporators in Your Facility

Exploring the Benefits of Using Rollbond Evaporators in Your Facility Introduction to Rollbond Evaporators Rollbond evaporators are increasingly becoming a key component in various industrial processes. Their unique design and operation principles make them an attractive choice for thermal management in facilities that require efficient heat transfer and evaporation processes. In this article, we

Published:

2025-05-28

source:

author:

Exploring the Benefits of Using Rollbond Evaporators in Your Facility

Introduction to Rollbond Evaporators

Rollbond evaporators are increasingly becoming a key component in various industrial processes. Their unique design and operation principles make them an attractive choice for thermal management in facilities that require efficient heat transfer and evaporation processes. In this article, we will delve deep into the benefits of using Rollbond evaporators in your facility and explore what makes them a superior choice for industrial applications.

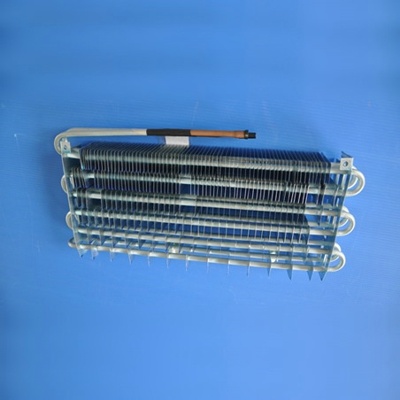

What is a Rollbond Evaporator?

A Rollbond evaporator is a specialized type of heat exchanger designed to facilitate the evaporation of liquids by efficiently transferring heat. The construction of these evaporators typically involves a thin metal sheet that is formed into a series of channels, allowing for optimal heat exchange. The innovative design leads to a highly compact unit, making it suitable for various applications in industries such as food processing, chemical manufacturing, and pharmaceuticals.

The Unique Design of Rollbond Evaporators

The unique design of Rollbond evaporators is one of their most significant advantages. Unlike traditional evaporators, which can be bulky and less efficient, Rollbond evaporators feature a compact and lightweight construction. This design offers several benefits:

- **Enhanced Heat Transfer Efficiency**: The thin metal sheets allow for greater surface area contact, ensuring effective heat transfer.

- **Space Savings**: Their compact size means they occupy less floor space, allowing for better utilization of your facility's layout.

- **Lightweight Construction**: The reduced weight simplifies installation and maintenance processes.

Key Benefits of Using Rollbond Evaporators

1. Improved Energy Efficiency

Rollbond evaporators are designed to minimize energy consumption while maximizing heat transfer efficiency. This translates into significant energy savings for your facility. By optimizing the evaporation process, these units help reduce operational costs, making them a financially viable option for industries aiming to cut expenses.

2. Versatility in Applications

One of the standout features of Rollbond evaporators is their versatility. They are suitable for various applications, including:

- **Food Processing**: Ideal for concentrating juices, dairy products, and other food liquids.

- **Chemical Manufacturing**: Used for evaporating solvents and concentrating chemical solutions.

- **Pharmaceuticals**: Essential for producing concentrated drugs and ensuring product consistency.

3. Enhanced Product Quality

Using Rollbond evaporators can significantly enhance the quality of the end product. The efficient heat exchange process minimizes the risk of thermal degradation, ensuring that sensitive materials maintain their integrity during evaporation. This is particularly crucial in industries like food and pharmaceuticals, where product quality is paramount.

4. Low Maintenance Requirements

Rollbond evaporators are designed for durability and reliability, resulting in lower maintenance needs compared to traditional evaporators. Their simple construction and fewer moving parts mean less wear and tear, leading to prolonged operational life and reduced downtime in your facility.

5. Environmental Impact Reduction

With a focus on energy efficiency, Rollbond evaporators contribute to a lower carbon footprint. By reducing energy consumption, these evaporators help facilities meet sustainability goals and comply with environmental regulations. This can enhance your company's reputation as an environmentally conscious organization.

Implementation Considerations for Rollbond Evaporators

1. System Compatibility

Before integrating Rollbond evaporators into your facility, it’s essential to consider system compatibility. Assess the existing infrastructure and ensure that the new evaporators can seamlessly integrate with current operations without significant modifications.

2. Initial Investment

While Rollbond evaporators offer long-term savings, the initial investment can be higher than traditional systems. It’s crucial to conduct a thorough cost-benefit analysis to ensure that the long-term savings justify the upfront expenses.

3. Training and Operational Knowledge

Training staff on the specific operation and maintenance of Rollbond evaporators is vital. Proper training ensures operators maximize the system's efficiency and maintain product quality during evaporation processes.

Frequently Asked Questions (FAQs)

What industries benefit the most from Rollbond evaporators?

Rollbond evaporators are particularly beneficial in the food processing, chemical manufacturing, and pharmaceutical industries due to their efficiency and ability to maintain product quality.

How do Rollbond evaporators compare to traditional evaporators?

Compared to traditional evaporators, Rollbond units offer improved energy efficiency, compact design, and low maintenance needs, making them a more attractive option for many facilities.

Are Rollbond evaporators easy to maintain?

Yes, Rollbond evaporators typically require less maintenance than traditional systems due to their durable design and fewer moving parts.

What is the typical lifespan of a Rollbond evaporator?

With proper maintenance, Rollbond evaporators can provide reliable service for many years, often outlasting traditional evaporators.

Can Rollbond evaporators be customized for specific applications?

Absolutely. Many manufacturers offer customization options to tailor Rollbond evaporators to specific industrial needs and applications.

Conclusion

In conclusion, Rollbond evaporators present a multitude of benefits for facilities looking to enhance efficiency, reduce operational costs, and improve product quality. Their unique design, energy efficiency, and versatility make them an ideal choice for various industries. By considering the implementation factors and ensuring compatibility with existing systems, facilities can successfully integrate Rollbond evaporators into their operations, leading to long-term savings and enhanced performance. The transition to Rollbond evaporators not only positions your facility for increased productivity but also aligns with sustainability goals, making it a win-win solution for modern industrial challenges.

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.