Unlocking Efficiency: The Role of Rollbond Evaporators in Industrial Processes

Unlocking Efficiency: The Role of Rollbond Evaporators in Industrial Processes Table of Contents 1. Introduction to Rollbond Evaporators 2. What Are Rollbond Evaporators? 3. Key Benefits of Rollbond Evaporators in Industrial Applications 4. Applications of Rollbond Evaporators in Various Industries 5. How Rollbond Evaporators Work: A Detailed Overview 6. Comparing Rollbond

Published:

2025-04-30

source:

author:

Unlocking Efficiency: The Role of Rollbond Evaporators in Industrial Processes

Table of Contents

- 1. Introduction to Rollbond Evaporators

- 2. What Are Rollbond Evaporators?

- 3. Key Benefits of Rollbond Evaporators in Industrial Applications

- 4. Applications of Rollbond Evaporators in Various Industries

- 5. How Rollbond Evaporators Work: A Detailed Overview

- 6. Comparing Rollbond Evaporators with Other Evaporators

- 7. Maintenance and Sustainability of Rollbond Evaporators

- 8. The Future of Rollbond Evaporators in Industrial Processes

- 9. FAQs about Rollbond Evaporators

- 10. Conclusion: The Role of Rollbond Evaporators in Enhancing Efficiency

1. Introduction to Rollbond Evaporators

In the realm of industrial processes, efficiency and reliability are paramount. Rollbond evaporators have emerged as a pivotal solution for enhancing thermal efficiency across a variety of applications. These innovative devices not only facilitate efficient heat transfer but also contribute to significant energy savings. By harnessing the unique design and operational principles of Rollbond technology, industries can unlock new levels of productivity and cost-effectiveness.

2. What Are Rollbond Evaporators?

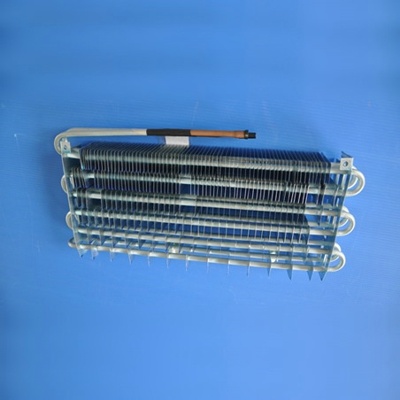

Rollbond evaporators are specialized thermal equipment designed for the efficient evaporation of liquids. The term "Rollbond" refers to the method by which the evaporator's heat exchange surfaces are manufactured, utilizing bonded metal layers to maximize surface area and enhance thermal conductivity. This advanced design allows for a compact and lightweight evaporator capable of performing under high-pressure and high-temperature conditions.

These evaporators are particularly effective in applications requiring rapid evaporation rates and precise temperature control, making them a preferred choice for many industrial sectors.

3. Key Benefits of Rollbond Evaporators in Industrial Applications

Understanding the benefits of Rollbond evaporators is essential for industries looking to optimize their processes. Here are some of the key advantages:

3.1 Enhanced Thermal Efficiency

Rollbond evaporators exhibit superior thermal performance due to their increased surface area and efficient heat transfer mechanisms. This leads to faster evaporation rates and reduced energy consumption.

3.2 Space Efficiency

The compact design of Rollbond evaporators makes them ideal for facilities with limited space. Their lightweight structure allows for easier installation and integration into existing systems.

3.3 Versatility in Applications

These evaporators are suitable for a wide range of applications, from food processing to chemical manufacturing, making them a versatile choice for various industrial needs.

3.4 Cost-Effectiveness

By improving energy efficiency and reducing operational costs, Rollbond evaporators can lead to significant savings over time. This cost-effectiveness is a crucial consideration for industries aiming to enhance their bottom line.

3.5 Improved Product Quality

With precise temperature control and rapid evaporation, Rollbond evaporators help maintain the quality and consistency of the final product, ensuring that industries meet their quality standards.

4. Applications of Rollbond Evaporators in Various Industries

Rollbond evaporators find applications across diverse sectors, each benefiting from their unique capabilities. Below are some examples:

4.1 Food and Beverage Industry

In food processing, Rollbond evaporators are utilized for concentrating juices, dairy products, and sauces. Their ability to operate at low temperatures ensures that the nutritional value and flavor of products remain intact.

4.2 Chemical Manufacturing

The chemical industry employs Rollbond evaporators for solvent recovery, waste treatment, and the concentration of various chemicals, significantly enhancing production efficiency.

4.3 Pharmaceutical Sector

In pharmaceuticals, these evaporators are crucial for producing active ingredients and concentrates, where precision and reliability are paramount.

4.4 Wastewater Treatment

Rollbond technology is employed in wastewater treatment processes, helping in the concentration of sludge and facilitating more efficient disposal methods.

5. How Rollbond Evaporators Work: A Detailed Overview

To fully appreciate the advantages of Rollbond evaporators, it's important to understand how they function.

5.1 Working Principle

Rollbond evaporators operate on the principle of heat transfer through bonded metal surfaces. The liquid to be evaporated is introduced into the evaporator, where it is heated by contact with these surfaces. As the liquid absorbs heat, it transforms into vapor and is subsequently removed from the system.

5.2 Design Features

The unique design of Rollbond evaporators includes a series of bonded panels that maximize surface area while minimizing volume. This allows for a more efficient heat exchange process, reducing the energy required for evaporation.

5.3 Temperature Control

Advanced temperature control systems are integrated into Rollbond evaporators, enabling precise regulation of heating and cooling cycles. This capability ensures optimal evaporation rates and enhances product quality.

6. Comparing Rollbond Evaporators with Other Evaporators

When evaluating evaporator options, it's beneficial to compare Rollbond technology with traditional evaporators.

6.1 Efficiency Comparison

Rollbond evaporators generally offer higher thermal efficiency compared to conventional evaporators, leading to reduced energy costs and faster processing times.

6.2 Space and Weight Considerations

Traditional evaporators can be bulky and heavy, whereas Rollbond evaporators are designed to be compact and lightweight, making them easier to install and maintain.

6.3 Versatility and Flexibility

While many evaporators are designed for specific applications, Rollbond evaporators are adaptable and can be utilized across multiple industries, offering greater flexibility.

7. Maintenance and Sustainability of Rollbond Evaporators

Proper maintenance is crucial for the longevity and efficiency of Rollbond evaporators.

7.1 Maintenance Best Practices

Regular inspections and cleanings are essential to ensure optimal performance. Operators should monitor for any signs of wear or corrosion and address issues promptly.

7.2 Sustainability Features

Rollbond evaporators contribute to sustainability efforts by reducing energy consumption and waste generation. Their high efficiency means less energy is required for operation, which can lead to lower emissions.

8. The Future of Rollbond Evaporators in Industrial Processes

As industries continue to evolve, the role of Rollbond evaporators is likely to expand.

8.1 Innovations in Technology

Ongoing advancements in materials and manufacturing techniques may enhance the performance of Rollbond evaporators, making them even more efficient in the future.

8.2 Increasing Demand

With a growing focus on sustainability and energy efficiency, the demand for Rollbond evaporators is expected to rise, positioning them as a key player in future industrial processes.

9. FAQs about Rollbond Evaporators

9.1 What industries commonly use Rollbond evaporators?

Rollbond evaporators are widely used in industries such as food and beverage, chemical manufacturing, pharmaceuticals, and wastewater treatment.

9.2 How do Rollbond evaporators compare to traditional evaporators in terms of energy efficiency?

Rollbond evaporators typically offer higher energy efficiency due to their advanced design, which allows for better heat transfer and reduced energy consumption.

9.3 What maintenance is required for Rollbond evaporators?

Regular inspections, cleaning, and monitoring for signs of wear are essential for maintaining Rollbond evaporators and ensuring their optimal performance.

9.4 Can Rollbond evaporators be customized for specific applications?

Yes, Rollbond evaporators can be designed and customized to meet the specific requirements of different industrial applications.

9.5 What is the typical lifespan of a Rollbond evaporator?

With proper maintenance, Rollbond evaporators can have a long lifespan, often exceeding that of traditional evaporators due to their robust design and materials.

10. Conclusion: The Role of Rollbond Evaporators in Enhancing Efficiency

In conclusion, Rollbond evaporators are revolutionizing industrial processes by unlocking new levels of efficiency and productivity. Their advanced design and superior thermal performance make them a valuable asset across various industries. By embracing Rollbond technology, businesses can not only improve their operational efficiency but also contribute to a more sustainable future. As the demand for innovative thermal solutions continues to grow, the significance of Rollbond evaporators will only increase, solidifying their place as a cornerstone of modern industrial processes.

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.