Why Rollbond Aluminum Plates Are Essential for Thermal Management

Introduction to Rollbond Aluminum Plates in Thermal Management In today's fast-paced industrial landscape, efficiently managing heat is crucial for ensuring optimal performance and longevity of equipment. **Rollbond aluminum plates** have emerged as a vital component in thermal management solutions across diverse applications. Their unique design and superior thermal conductivity make them indispe

Published:

2025-04-16

source:

author:

Introduction to Rollbond Aluminum Plates in Thermal Management

In today's fast-paced industrial landscape, efficiently managing heat is crucial for ensuring optimal performance and longevity of equipment. **Rollbond aluminum plates** have emerged as a vital component in thermal management solutions across diverse applications. Their unique design and superior thermal conductivity make them indispensable in industries ranging from automotive to HVAC systems. This article delves deeply into why Rollbond aluminum plates are essential for effective thermal management, exploring their benefits, applications, and technology.

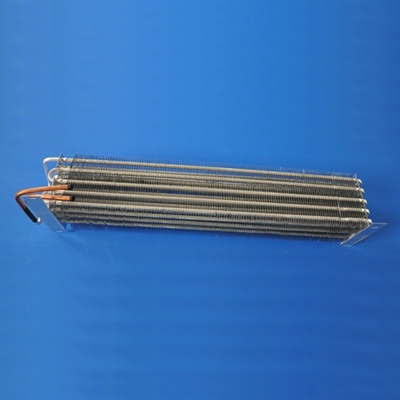

Understanding Rollbond Aluminum Plates

Rollbond aluminum plates are specifically engineered aluminum sheets that feature a bonded construction. This innovative method involves rolling two thin aluminum sheets together, creating an internal channel structure that enhances heat transfer efficiency. The design not only reduces weight but also optimizes space, which is particularly beneficial in applications where every millimeter counts.

Key Characteristics of Rollbond Aluminum Plates

1. **Lightweight Design**: Compared to traditional metal components, Rollbond aluminum plates offer a significantly lighter option, enabling easier handling and installation without sacrificing strength.

2. **Excellent Thermal Conductivity**: Aluminum’s natural thermal conductivity is enhanced in Rollbond plates, allowing for efficient heat exchange in various applications.

3. **Corrosion Resistance**: The aluminum material is inherently resistant to rust and corrosion, ensuring that the plates maintain their integrity even in harsh environments.

4. **Versatile Customization**: Rollbond plates can be tailored to meet specific requirements, including thickness, surface treatments, and dimensions, making them adaptable for a wide range of thermal management solutions.

The Importance of Thermal Management

Effective thermal management is critical across many industries. It ensures that equipment operates within safe temperature ranges, preventing overheating and subsequent damage. With rising operational temperatures, especially in electronic and mechanical systems, the need for efficient heat dissipation mechanisms has never been more pressing.

Consequences of Inefficient Thermal Management

Failing to manage heat effectively can lead to several issues, including:

- **Reduced Equipment Lifespan**: Prolonged exposure to high temperatures can accelerate wear and tear on machinery.

- **Increased Energy Costs**: Inefficient systems require more energy to maintain desired operating temperatures.

- **Safety Hazards**: Overheating can lead to catastrophic failures, posing serious safety risks to operators and equipment.

Applications of Rollbond Aluminum Plates

Rollbond aluminum plates find applications in various sectors, illustrating their versatility and effectiveness in thermal management solutions.

1. Automotive Industry

In the automotive sector, Rollbond aluminum plates are employed in heat exchangers, radiators, and engine cooling systems. The lightweight nature of these plates contributes to improved fuel efficiency without compromising performance.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from the heat transfer capabilities of Rollbond aluminum plates. By enhancing the efficiency of heat exchangers, these plates ensure optimal climate control in residential and commercial spaces.

3. Electronics Cooling

Rapid advancements in electronics have led to increased heat generation in devices. Rollbond aluminum plates are used in cooling systems for computers, servers, and other electronic equipment, preventing overheating and maintaining performance.

4. Renewable Energy Systems

In renewable energy applications, such as solar thermal systems, Rollbond aluminum plates can improve the efficiency of heat collection and transfer, making them invaluable for sustainable energy solutions.

The Technology Behind Rollbond Aluminum Plates

Understanding the manufacturing process of Rollbond aluminum plates provides insight into their effectiveness in thermal management. The production involves several key steps:

1. Roll-Bonding Process

The roll-bonding technique creates a thin-walled structure that facilitates the formation of internal flow channels. This process enhances the surface area available for heat exchange and maximizes thermal efficiency.

2. Surface Treatment

Surface treatments, such as anodizing and coating, can be applied to improve the corrosion resistance and durability of Rollbond plates, extending their operational lifespan even in demanding environments.

3. Quality Control

Stringent quality control measures ensure that each Rollbond aluminum plate meets industry standards for thermal conductivity, weight, and structural integrity.

Advantages of Using Rollbond Aluminum Plates

The adoption of Rollbond aluminum plates brings numerous advantages to organizations seeking reliable thermal management solutions.

1. Enhanced Efficiency

By optimizing heat transfer capabilities, Rollbond plates contribute to the smoother operation of systems, leading to reduced energy consumption and lower operating costs.

2. Lightweight and Compact

The reduction in weight allows for easier installation and integration into existing systems, a crucial factor in modern design where space optimization is required.

3. Longevity and Reliability

Due to their corrosion-resistant properties and robust construction, Rollbond aluminum plates provide a long-lasting solution, minimizing the need for frequent replacements.

Challenges and Considerations

Despite their numerous benefits, the use of Rollbond aluminum plates does come with certain challenges that industries must consider.

1. Initial Cost**: While the long-term benefits often outweigh the initial investment, the upfront cost of Rollbond plates may be higher than traditional metal alternatives.

2. Specialized Manufacturing**: The production process requires specialized equipment and expertise, which may limit availability in some regions.

3. Compatibility with Other Materials**: Ensuring compatibility with other materials in thermal management systems is crucial for optimizing performance.

FAQs about Rollbond Aluminum Plates and Thermal Management

1. What industries commonly use Rollbond aluminum plates?

Rollbond aluminum plates are used in various industries, including automotive, HVAC, electronics, and renewable energy.

2. How do Rollbond aluminum plates improve thermal efficiency?

Their design increases the surface area for heat exchange, promoting enhanced thermal conductivity and efficient heat dissipation.

3. Are Rollbond aluminum plates expensive?

While the initial cost may be higher than traditional materials, their long-term benefits and durability often provide a better return on investment.

4. Can Rollbond aluminum plates be customized?

Yes, Rollbond plates can be tailored in terms of thickness, dimensions, and surface treatments to meet specific application requirements.

5. What maintenance do Rollbond aluminum plates require?

Generally, they require minimal maintenance due to their corrosion-resistant properties, but regular inspections can help ensure optimal performance.

Conclusion: The Role of Rollbond Aluminum Plates in Future Thermal Management

In conclusion, Rollbond aluminum plates are essential components in the realm of thermal management. Their unique properties and advantages make them a preferred choice across various industries. As technology evolves and the demand for efficient thermal solutions increases, the role of Rollbond aluminum plates will undoubtedly expand, driving innovation and sustainability in thermal management practices. By embracing this technology, industries can enhance performance, reduce costs, and contribute to a more efficient future.

3. Compatibility with Other Materials**: Ensuring compatibility with other materials in thermal management systems is crucial for optimizing performance.

FAQs about Rollbond Aluminum Plates and Thermal Management

1. What industries commonly use Rollbond aluminum plates?

Rollbond aluminum plates are used in various industries, including automotive, HVAC, electronics, and renewable energy.

2. How do Rollbond aluminum plates improve thermal efficiency?

Their design increases the surface area for heat exchange, promoting enhanced thermal conductivity and efficient heat dissipation.

3. Are Rollbond aluminum plates expensive?

While the initial cost may be higher than traditional materials, their long-term benefits and durability often provide a better return on investment.

4. Can Rollbond aluminum plates be customized?

Yes, Rollbond plates can be tailored in terms of thickness, dimensions, and surface treatments to meet specific application requirements.

5. What maintenance do Rollbond aluminum plates require?

Generally, they require minimal maintenance due to their corrosion-resistant properties, but regular inspections can help ensure optimal performance.

Conclusion: The Role of Rollbond Aluminum Plates in Future Thermal Management

In conclusion, Rollbond aluminum plates are essential components in the realm of thermal management. Their unique properties and advantages make them a preferred choice across various industries. As technology evolves and the demand for efficient thermal solutions increases, the role of Rollbond aluminum plates will undoubtedly expand, driving innovation and sustainability in thermal management practices. By embracing this technology, industries can enhance performance, reduce costs, and contribute to a more efficient future.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.