Exploring Rollbond Aluminum Plates: Revolutionizing Heat Exchange Equipment

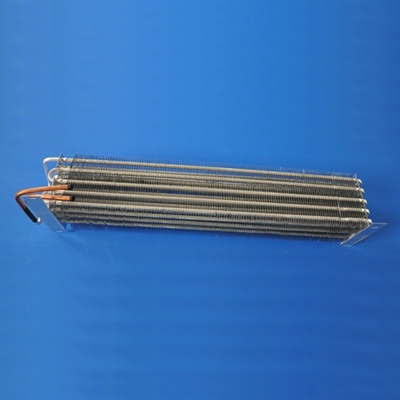

Rollbond aluminum plates are gaining traction in the industrial equipment sector, particularly in heat exchange applications. These plates are manufactured through a unique process that involves bonding two or more layers of aluminum together, creating a lightweight and highly efficient product. Their distinctive design and structure make them an ideal choice for various heat transfer applications

Published:

2025-04-09

source:

author:

Rollbond aluminum plates are gaining traction in the industrial equipment sector, particularly in heat exchange applications. These plates are manufactured through a unique process that involves bonding two or more layers of aluminum together, creating a lightweight and highly efficient product. Their distinctive design and structure make them an ideal choice for various heat transfer applications.

One of the key advantages of rollbond aluminum plates is their excellent thermal conductivity. Aluminum is known for its ability to conduct heat efficiently, and when layers are bonded together, it enhances the overall heat transfer performance. This feature is critical in applications where controlling temperature is essential, such as in HVAC systems, refrigeration, and industrial process cooling.

Another significant benefit of rollbond aluminum plates is their lightweight nature. Compared to traditional heat exchangers made from heavier materials, these plates are easier to handle and install. This can lead to reduced transportation costs and simpler assembly processes, making them a more practical solution for many industrial settings.

The rollbonding process also allows for the creation of intricate designs, including complex geometries that enhance surface area for heat exchange. Increased surface area improves the efficiency of heat transfer, leading to more effective cooling or heating in various applications. This is especially advantageous in compact systems where space is limited.

Furthermore, rollbond aluminum plates offer excellent corrosion resistance. Aluminum naturally forms a protective oxide layer that helps prevent corrosion, making these plates suitable for use in environments where exposure to moisture or corrosive substances is a concern. This durability contributes to the longevity of heat exchange equipment, minimizing maintenance requirements and extending operational life.

In terms of applications, rollbond aluminum plates are utilized in a wide range of industries, including automotive, chemical processing, and food and beverage. Their versatility makes them suitable for both high and low-pressure applications, positioning them as a favored choice among engineers and equipment manufacturers.

In conclusion, rollbond aluminum plates represent a significant advancement in heat exchange technology. Their superior thermal conductivity, lightweight structure, intricate design possibilities, and corrosion resistance make them an ideal solution for various industrial applications. As industries continue to seek efficient and durable heat exchange solutions, rollbond aluminum plates are poised to play a pivotal role in the future of thermal management solutions. For professionals in the field, understanding the benefits and applications of rollbond aluminum plates can lead to more informed decision-making when selecting heat exchange equipment.

One of the key advantages of rollbond aluminum plates is their excellent thermal conductivity. Aluminum is known for its ability to conduct heat efficiently, and when layers are bonded together, it enhances the overall heat transfer performance. This feature is critical in applications where controlling temperature is essential, such as in HVAC systems, refrigeration, and industrial process cooling.

Another significant benefit of rollbond aluminum plates is their lightweight nature. Compared to traditional heat exchangers made from heavier materials, these plates are easier to handle and install. This can lead to reduced transportation costs and simpler assembly processes, making them a more practical solution for many industrial settings.

The rollbonding process also allows for the creation of intricate designs, including complex geometries that enhance surface area for heat exchange. Increased surface area improves the efficiency of heat transfer, leading to more effective cooling or heating in various applications. This is especially advantageous in compact systems where space is limited.

Furthermore, rollbond aluminum plates offer excellent corrosion resistance. Aluminum naturally forms a protective oxide layer that helps prevent corrosion, making these plates suitable for use in environments where exposure to moisture or corrosive substances is a concern. This durability contributes to the longevity of heat exchange equipment, minimizing maintenance requirements and extending operational life.

In terms of applications, rollbond aluminum plates are utilized in a wide range of industries, including automotive, chemical processing, and food and beverage. Their versatility makes them suitable for both high and low-pressure applications, positioning them as a favored choice among engineers and equipment manufacturers.

In conclusion, rollbond aluminum plates represent a significant advancement in heat exchange technology. Their superior thermal conductivity, lightweight structure, intricate design possibilities, and corrosion resistance make them an ideal solution for various industrial applications. As industries continue to seek efficient and durable heat exchange solutions, rollbond aluminum plates are poised to play a pivotal role in the future of thermal management solutions. For professionals in the field, understanding the benefits and applications of rollbond aluminum plates can lead to more informed decision-making when selecting heat exchange equipment.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.