PRODUCT CATEGORY

Service hotline:

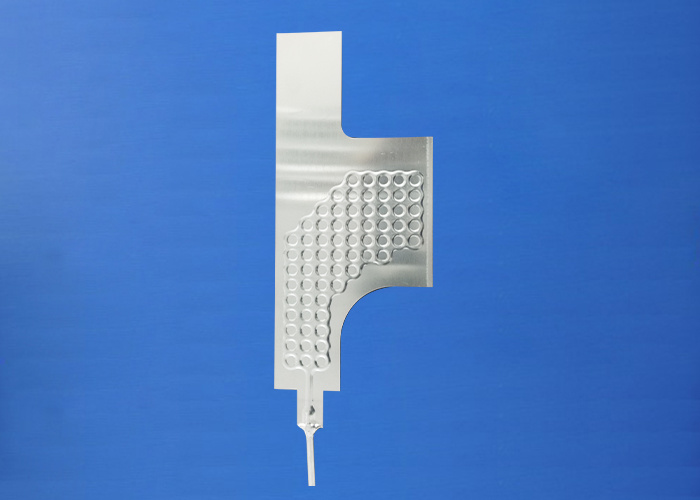

Rollbond Aluminum Plate

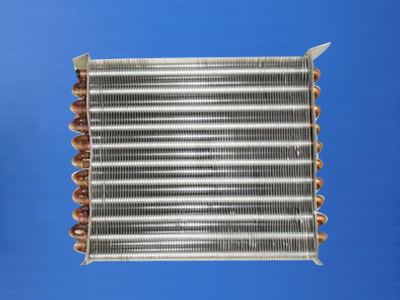

The company's main products are: Rollbond evaporators, fin evaporators etc.

Category:

key word:

Rollbond Aluminum Plate

Contact Now

product details

Detailed introduction:

Rollbond aluminum plate is a type of composite material made from high-quality aluminum and a thermoplastic bonding layer. The bonding layer is typically made from a polymer material such as polyethylene, which allows the aluminum plate to adhere to other materials without the need for an additional adhesive. Rollbond aluminum plates are widely used in a variety of industries due to their excellent thermal conductivity, corrosion resistance, and durability.

One of the primary applications of rollbond aluminum plate is in the production of heat exchangers. These heat exchangers are used in a range of industrial and commercial settings, including air conditioning systems, refrigeration units, and automotive cooling systems. The high thermal conductivity of rollbond aluminum plate facilitates efficient heat transfer, allowing for more effective temperature control and energy savings.

In addition to heat exchangers, rollbond aluminum plate is also used in the manufacturing of lightweight, yet strong, structural components. Due to its excellent corrosion resistance and durability, rollbond aluminum plate can be used in harsh environments where traditional materials such as steel would quickly corrode and degrade.

Rollbond aluminum plate is also highly customizable, with a variety of thicknesses, widths, and lengths available depending on the specific needs of a particular application. Additionally, the thermoplastic bonding layer can be tailored to meet specific performance requirements, such as temperature resistance or chemical compatibility.

Overall, rollbond aluminum plate is a versatile and reliable material that is used in a wide variety of industrial and commercial applications. With its excellent thermal conductivity, corrosion resistance, and durability, it offers superior performance compared to many traditional materials and has become an essential component in many modern manufacturing processes.

R134a Refrigeration System Inner Tube Standard

| Residual oil content | ≤7mg/㎡ | |

| residual impurities | ≤60mg/㎡ | |

| Single impurity | ≤2mg | |

| Content volume/cm3 | Residual water mg | |

| ≤100 | ≤10 | |

| Residual water | 101-200 | ≤20 |

| 201-400 | ≤25 | |

| 401-800 | ≤30 | |

Coating quality performance standard

| Coating thickness | Coating thickness ≥ 0.04mm |

| Coating hardness | ≥2H |

| Coating impact resistance | 50 ㎝ · ㎏ / ㎝ impact resistance without cracking |

| Coating adhesion | ≥ Level 2 |

| Coating flexibility | Bending R = 3D, bending angle 180 °, coating without cracking or falling off |

| Dust coating color difference | △ E≤1.5 |

Recommended products

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!

Mobile website

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.