Rollbond Plates: Enhancing the Efficiency of Commercial Cooling Units

Rollbond Plates: Enhancing the Efficiency of Commercial Cooling Units Table of Contents Understanding Rollbond Plates Design and Structure of Rollbond Plates Benefits of Using Rollbond Plates in Cooling Systems Applications of Rollbond Plates in Refrigeration Comparison with Traditional Cooling Methods Installation and Maintenance of Rollbond Plates Future Trends in Co

Published:

2025-06-11

source:

author:

Rollbond Plates: Enhancing the Efficiency of Commercial Cooling Units

Table of Contents

- Understanding Rollbond Plates

- Design and Structure of Rollbond Plates

- Benefits of Using Rollbond Plates in Cooling Systems

- Applications of Rollbond Plates in Refrigeration

- Comparison with Traditional Cooling Methods

- Installation and Maintenance of Rollbond Plates

- Future Trends in Cooling Technology

- FAQs About Rollbond Plates

- Conclusion

Understanding Rollbond Plates

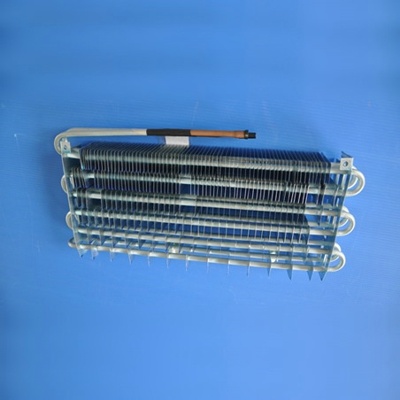

Rollbond plates are a sophisticated component in the realm of refrigeration, designed to enhance the efficiency of commercial cooling units. These plates are formed using a unique process that involves bonding two metal sheets together, creating a space that can be filled with refrigerant. This innovative design allows for superior thermal conductivity and efficiency compared to conventional cooling methods.

The primary purpose of Rollbond plates is to maximize the surface area available for heat exchange, which is crucial in commercial cooling systems. The enhanced surface area enables better heat transfer, resulting in improved energy efficiency and reduced operational costs.

Design and Structure of Rollbond Plates

The design of Rollbond plates plays a critical role in their functionality. They typically consist of two sheets of metal, usually aluminum, that are bonded together through a combination of heat and pressure. This process creates a series of channels or cavities within the plates that allow the refrigerant to flow.

The internal structure can be customized based on the specific cooling requirements of the application. For instance, varying the depth and width of the channels can significantly impact the heat exchange efficiency. Furthermore, the lightweight nature of Rollbond plates makes them an ideal choice for commercial cooling units, as they reduce the overall weight of the system without compromising strength.

Key Features of Rollbond Plates

1. **High Thermal Conductivity**: The aluminum material used in Rollbond plates offers excellent thermal conductivity, allowing for efficient heat transfer.

2. **Lightweight Design**: The reduced weight makes installation easier and lessens the structural load on the cooling unit.

3. **Customizable Configuration**: Flexibility in design allows for tailored solutions for different cooling needs, optimizing performance based on specific application requirements.

Benefits of Using Rollbond Plates in Cooling Systems

Integrating Rollbond plates into commercial cooling units provides several significant benefits:

Enhanced Energy Efficiency

One of the primary advantages of Rollbond plates is their ability to improve energy efficiency. By maximizing the heat exchange surface area, these plates allow for quicker cooling and heating cycles, leading to less energy consumption. This efficiency not only reduces operational costs but also contributes to a smaller carbon footprint, aligning with global sustainability goals.

Cost-Effectiveness

While the initial investment in Rollbond technology may be higher compared to traditional cooling methods, the long-term savings on energy bills often justify the cost. Fewer energy resources used result in lower operational costs over time, making it a financially sound choice for businesses.

Improved Performance and Reliability

Rollbond plates are known for their robustness and durability. Their design minimizes the likelihood of leaks and failures common in traditional cooling systems. This reliability translates into fewer maintenance requirements and extended service life for cooling units.

Applications of Rollbond Plates in Refrigeration

Rollbond plates have diverse applications within the refrigeration sector. Their versatile nature allows them to be utilized in various cooling systems, including:

Commercial Refrigeration Units

Supermarkets and restaurants benefit from Rollbond plates in their refrigeration units, ensuring that food and beverages remain at optimal temperatures.

Industrial Cooling Systems

In industrial settings, Rollbond plates are crucial for processes that require precise temperature control, such as chemical manufacturing and pharmaceuticals.

Air Conditioning Systems

Rollbond technology is increasingly being incorporated into air conditioning systems, providing enhanced cooling performance and energy savings.

Comparison with Traditional Cooling Methods

When comparing Rollbond plates to traditional cooling methods, several distinct advantages emerge:

Efficiency

Traditional cooling systems often rely on bulky components that limit heat transfer capabilities. In contrast, Rollbond plates maximize efficiency through their design, resulting in faster cooling cycles and reduced energy requirements.

Space Optimization

Rollbond plates occupy less space within cooling units than conventional heat exchangers, allowing for more compact system designs. This space-saving feature is particularly beneficial in commercial settings where floor space is at a premium.

Environmental Impact

By lowering energy consumption, Rollbond plates contribute to reduced greenhouse gas emissions. This makes them an environmentally friendly alternative to traditional cooling methods that may rely on less efficient technologies.

Installation and Maintenance of Rollbond Plates

Proper installation and maintenance are crucial for maximizing the performance of Rollbond plates in cooling systems.

Installation Process

The installation process typically involves integrating the Rollbond plates into the cooling unit's design. This may require specialized equipment and trained technicians to ensure a proper fit and optimal performance.

Maintenance Best Practices

To maintain the effectiveness of Rollbond plates, regular inspections are recommended. Checking for signs of wear, ensuring proper refrigerant flow, and cleaning surfaces are essential practices. These steps help prevent efficiency losses and extend the lifespan of the cooling unit.

Future Trends in Cooling Technology

As the demand for efficient and sustainable cooling solutions grows, Rollbond plates are poised to play a significant role in the evolution of cooling technology. Emerging trends include:

Smart Cooling Systems

Integration of smart technology in cooling systems is on the rise. Rollbond plates can be incorporated into these systems, allowing for real-time monitoring and optimization based on usage patterns.

Eco-Friendly Refrigerants

The shift towards environmentally friendly refrigerants aligns with the benefits of Rollbond plates. Their efficiency can enhance the performance of alternative refrigerants, contributing to a more sustainable cooling solution.

FAQs About Rollbond Plates

1. What are Rollbond plates made of?

Rollbond plates are typically made from aluminum, providing excellent thermal conductivity and lightweight properties.

2. How do Rollbond plates improve energy efficiency?

Their design maximizes surface area for heat exchange, resulting in faster cooling cycles and reduced energy consumption.

3. Are Rollbond plates suitable for all types of cooling systems?

Yes, Rollbond plates can be customized for various applications, including commercial refrigeration, industrial cooling, and air conditioning systems.

4. What maintenance is required for Rollbond plates?

Regular inspections for wear and proper refrigerant flow, along with surface cleaning, help maintain their efficiency.

5. How do Rollbond plates compare to traditional heat exchangers?

Rollbond plates offer higher efficiency, reduced size, and improved environmental impact compared to traditional heat exchangers.

Conclusion

Rollbond plates represent a transformative technology in the realm of commercial cooling units, enhancing efficiency, performance, and sustainability. Their innovative design and robust benefits make them an invaluable choice for businesses aiming to optimize their refrigeration systems. As we continue to push the boundaries of cooling technology, Rollbond plates will undoubtedly play a pivotal role in shaping the future of efficient cooling solutions. Investing in Rollbond technology is not just a smart choice; it is a step towards a greener and more sustainable future in the refrigeration industry.

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.