The Power of Aluminum Plates in Heat Exchanger Efficiency

Table of Contents: 1. Introduction 2. Understanding Heat Exchangers 3. The Role of Aluminum Plates in Heat Exchangers 4. Advantages of Aluminum Plates in Heat Exchanger Efficiency 5. The Effectiveness of Aluminum Plate Heat Exchangers 6. Applications of Aluminum Plate Heat Exchangers 7. Frequently Asked Questions (FAQs) 8. Conclusion 1. Introduction The constantly evolving industrial equipment and

Published:

2024-02-11

source:

author:

Table of Contents:

1. Introduction

2. Understanding Heat Exchangers

3. The Role of Aluminum Plates in Heat Exchangers

4. Advantages of Aluminum Plates in Heat Exchanger Efficiency

5. The Effectiveness of Aluminum Plate Heat Exchangers

6. Applications of Aluminum Plate Heat Exchangers

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction

The constantly evolving industrial equipment and components sector continually seeks innovative solutions to optimize energy consumption. In this article, we explore the incredible efficiency of aluminum plates in heat exchangers. These devices play a pivotal role in improving heat transfer, enhancing energy efficiency, and contributing to sustainable development.

2. Understanding Heat Exchangers

Heat exchangers are vital components used in various industries to transfer thermal energy between two or more fluids. They are designed to efficiently exchange heat while minimizing energy loss. Heat exchangers find applications in heating, cooling, and refrigeration systems, as well as in power plants and HVAC systems.

3. The Role of Aluminum Plates in Heat Exchangers

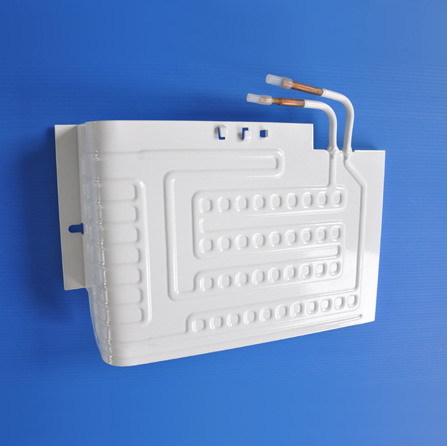

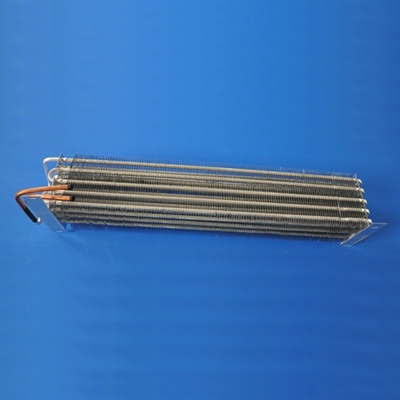

Aluminum plates are extensively used in heat exchangers due to their exceptional thermal conductivity, lightweight nature, and corrosion resistance. These plates act as the primary surface for heat transfer, allowing efficient exchange between two fluids. Their unique properties make them ideal for applications where high heat transfer rates and compact designs are required.

4. Advantages of Aluminum Plates in Heat Exchanger Efficiency

4.1 Enhanced Heat Transfer: Aluminum plates possess excellent thermal conductivity, enabling rapid heat transfer between fluids. This property significantly improves the efficiency of heat exchangers, reducing energy consumption and promoting cost-effectiveness.

4.2 Lightweight Design: The lightweight nature of aluminum plates makes heat exchangers more compact and easier to install. This feature is particularly advantageous in industries where space is limited, enabling the development of compact equipment without compromising efficiency.

4.3 Corrosion Resistance: Aluminum plates are highly resistant to corrosion, ensuring the longevity and durability of heat exchangers. This resistance eliminates the need for frequent maintenance and replacement, reducing downtime and increasing overall operational efficiency.

4.4 Cost-Effectiveness: The abundance and affordability of aluminum make it a cost-effective choice for heat exchangers. With lower production costs and longer lifespans, aluminum plate heat exchangers offer an economic advantage for industries striving to optimize energy consumption.

5. The Effectiveness of Aluminum Plate Heat Exchangers

Aluminum plate heat exchangers demonstrate exceptional effectiveness in various applications. Their efficient heat transfer capabilities, combined with lightweight design and corrosion resistance, contribute to their widespread usage. Industries such as automotive, HVAC, power generation, and chemical processing benefit significantly from the use of aluminum plate heat exchangers.

6. Applications of Aluminum Plate Heat Exchangers

6.1 Automotive Industry: Aluminum plate heat exchangers are widely employed in automotive cooling systems, enabling efficient heat dissipation and temperature regulation. They play a crucial role in maintaining engine performance and preventing overheating.

6.2 HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize aluminum plate heat exchangers for efficient temperature control. These devices facilitate the exchange of heat between indoor and outdoor environments, ensuring optimal comfort and energy efficiency.

6.3 Power Generation: Aluminum plate heat exchangers are utilized in power plants to enhance energy efficiency by efficiently transferring heat between different stages of power generation processes. These exchangers contribute to sustainable development by reducing energy wastage.

6.4 Chemical Processing: In chemical plants, aluminum plate heat exchangers are employed for precise temperature control during various chemical reactions and processes. Their excellent heat transfer properties enable efficient heat management, contributing to improved productivity and reduced environmental impact.

7. Frequently Asked Questions (FAQs)

1. How does the thermal conductivity of aluminum plates affect heat exchanger efficiency?

2. Are aluminum plate heat exchangers suitable for high-temperature applications?

3. What maintenance is required for aluminum plate heat exchangers?

4. How do aluminum plate heat exchangers contribute to energy conservation?

5. Can aluminum plates be customized for specific heat exchanger designs?

8. Conclusion

In conclusion, the power of aluminum plates in heat exchanger efficiency is undeniable. These remarkable devices optimize heat transfer, enhance energy efficiency, and contribute to sustainable development. With their exceptional thermal conductivity, lightweight design, and corrosion resistance, aluminum plate heat exchangers revolutionize the industrial equipment and components industry. Embracing these innovative solutions not only improves operational efficiency but also reduces energy consumption, making a positive impact on both businesses and the environment.

1. Introduction

2. Understanding Heat Exchangers

3. The Role of Aluminum Plates in Heat Exchangers

4. Advantages of Aluminum Plates in Heat Exchanger Efficiency

5. The Effectiveness of Aluminum Plate Heat Exchangers

6. Applications of Aluminum Plate Heat Exchangers

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction

The constantly evolving industrial equipment and components sector continually seeks innovative solutions to optimize energy consumption. In this article, we explore the incredible efficiency of aluminum plates in heat exchangers. These devices play a pivotal role in improving heat transfer, enhancing energy efficiency, and contributing to sustainable development.

2. Understanding Heat Exchangers

Heat exchangers are vital components used in various industries to transfer thermal energy between two or more fluids. They are designed to efficiently exchange heat while minimizing energy loss. Heat exchangers find applications in heating, cooling, and refrigeration systems, as well as in power plants and HVAC systems.

3. The Role of Aluminum Plates in Heat Exchangers

Aluminum plates are extensively used in heat exchangers due to their exceptional thermal conductivity, lightweight nature, and corrosion resistance. These plates act as the primary surface for heat transfer, allowing efficient exchange between two fluids. Their unique properties make them ideal for applications where high heat transfer rates and compact designs are required.

4. Advantages of Aluminum Plates in Heat Exchanger Efficiency

4.1 Enhanced Heat Transfer: Aluminum plates possess excellent thermal conductivity, enabling rapid heat transfer between fluids. This property significantly improves the efficiency of heat exchangers, reducing energy consumption and promoting cost-effectiveness.

4.2 Lightweight Design: The lightweight nature of aluminum plates makes heat exchangers more compact and easier to install. This feature is particularly advantageous in industries where space is limited, enabling the development of compact equipment without compromising efficiency.

4.3 Corrosion Resistance: Aluminum plates are highly resistant to corrosion, ensuring the longevity and durability of heat exchangers. This resistance eliminates the need for frequent maintenance and replacement, reducing downtime and increasing overall operational efficiency.

4.4 Cost-Effectiveness: The abundance and affordability of aluminum make it a cost-effective choice for heat exchangers. With lower production costs and longer lifespans, aluminum plate heat exchangers offer an economic advantage for industries striving to optimize energy consumption.

5. The Effectiveness of Aluminum Plate Heat Exchangers

Aluminum plate heat exchangers demonstrate exceptional effectiveness in various applications. Their efficient heat transfer capabilities, combined with lightweight design and corrosion resistance, contribute to their widespread usage. Industries such as automotive, HVAC, power generation, and chemical processing benefit significantly from the use of aluminum plate heat exchangers.

6. Applications of Aluminum Plate Heat Exchangers

6.1 Automotive Industry: Aluminum plate heat exchangers are widely employed in automotive cooling systems, enabling efficient heat dissipation and temperature regulation. They play a crucial role in maintaining engine performance and preventing overheating.

6.2 HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize aluminum plate heat exchangers for efficient temperature control. These devices facilitate the exchange of heat between indoor and outdoor environments, ensuring optimal comfort and energy efficiency.

6.3 Power Generation: Aluminum plate heat exchangers are utilized in power plants to enhance energy efficiency by efficiently transferring heat between different stages of power generation processes. These exchangers contribute to sustainable development by reducing energy wastage.

6.4 Chemical Processing: In chemical plants, aluminum plate heat exchangers are employed for precise temperature control during various chemical reactions and processes. Their excellent heat transfer properties enable efficient heat management, contributing to improved productivity and reduced environmental impact.

7. Frequently Asked Questions (FAQs)

1. How does the thermal conductivity of aluminum plates affect heat exchanger efficiency?

2. Are aluminum plate heat exchangers suitable for high-temperature applications?

3. What maintenance is required for aluminum plate heat exchangers?

4. How do aluminum plate heat exchangers contribute to energy conservation?

5. Can aluminum plates be customized for specific heat exchanger designs?

8. Conclusion

In conclusion, the power of aluminum plates in heat exchanger efficiency is undeniable. These remarkable devices optimize heat transfer, enhance energy efficiency, and contribute to sustainable development. With their exceptional thermal conductivity, lightweight design, and corrosion resistance, aluminum plate heat exchangers revolutionize the industrial equipment and components industry. Embracing these innovative solutions not only improves operational efficiency but also reduces energy consumption, making a positive impact on both businesses and the environment.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.