Choosing the Right Aluminum Plate for Your Refrigerator

Table of Contents: 1. Introduction: Understanding the Importance of Aluminum Plates in Refrigerators 2. The Role of Aluminum Plates in Refrigerator Efficiency 3. Factors to Consider When Choosing an Aluminum Plate a. Thickness and Strength b. Heat Transfer Capability c. Corrosion Resistance d. Weight and Structural Integrity 4. Different Types of Aluminum Plates for Refrigerators

Published:

2024-01-30

source:

author:

Table of Contents:

1. Introduction: Understanding the Importance of Aluminum Plates in Refrigerators

2. The Role of Aluminum Plates in Refrigerator Efficiency

3. Factors to Consider When Choosing an Aluminum Plate

a. Thickness and Strength

b. Heat Transfer Capability

c. Corrosion Resistance

d. Weight and Structural Integrity

4. Different Types of Aluminum Plates for Refrigerators

a. 1xxx Series Aluminum Plates

b. 3xxx Series Aluminum Plates

c. 5xxx Series Aluminum Plates

d. 6xxx Series Aluminum Plates

5. Frequently Asked Questions (FAQs)

a. What is the ideal thickness for an aluminum plate in a refrigerator?

b. How does the heat transfer capability of different aluminum plates vary?

c. Can aluminum plates resist corrosion effectively?

d. Does the weight of the aluminum plate impact refrigerator performance?

e. Are there any specific regulations for using aluminum plates in refrigerators?

6. Conclusion: Making the Right Choice for Optimal Refrigerator Performance

1. Introduction: Understanding the Importance of Aluminum Plates in Refrigerators

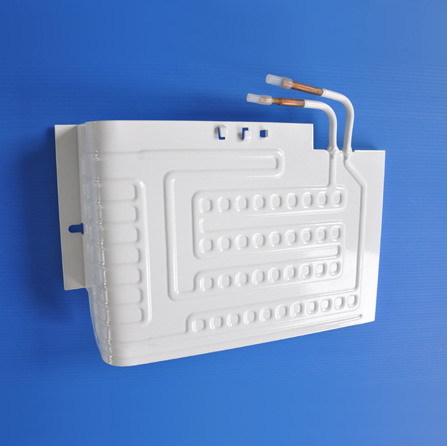

In the world of modern refrigeration, aluminum plates play a vital role in ensuring optimal performance and efficiency. These plates are used for various applications, including heat exchange, structural support, and even aesthetic enhancements. Choosing the right aluminum plate is crucial to maximize the performance and longevity of your refrigerator.

2. The Role of Aluminum Plates in Refrigerator Efficiency

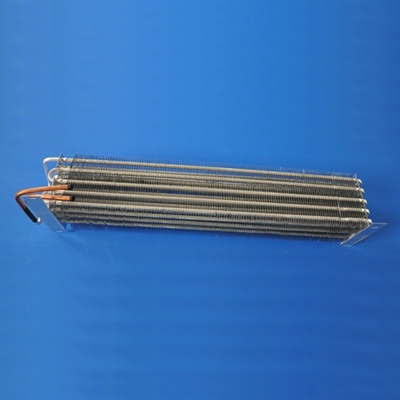

Aluminum plates are primarily responsible for facilitating heat transfer within refrigerators. These plates act as conductors, absorbing heat from the interior of the refrigerator and releasing it to the surrounding environment. By efficiently transferring heat, aluminum plates help maintain a stable temperature inside the refrigerator, ensuring the freshness and longevity of stored food.

3. Factors to Consider When Choosing an Aluminum Plate

a. Thickness and Strength

The thickness and strength of an aluminum plate are critical factors to consider. Thicker plates offer better structural integrity and durability, ensuring long-term performance. Additionally, thicker plates can withstand higher pressure differentials, making them suitable for heavy-duty refrigerators.

b. Heat Transfer Capability

The heat transfer capability of an aluminum plate determines its efficiency in absorbing and dissipating heat. Look for plates with high thermal conductivity, as they will facilitate faster heat exchange, leading to improved refrigerator efficiency and reduced energy consumption.

c. Corrosion Resistance

Refrigerators are exposed to moisture and various chemical agents, making corrosion resistance a vital consideration. Opt for aluminum plates with a protective coating or alloys that offer excellent corrosion resistance, ensuring the longevity of both the plate and the refrigerator.

d. Weight and Structural Integrity

The weight of the aluminum plate affects the overall weight of the refrigerator. Lighter plates are preferred, as they reduce the load on the refrigerator's components without compromising structural integrity. Consider plates with high strength-to-weight ratios for optimal performance.

4. Different Types of Aluminum Plates for Refrigerators

a. 1xxx Series Aluminum Plates

1xxx series aluminum plates are pure aluminum, known for their excellent corrosion resistance and thermal conductivity. These plates are commonly used in refrigerators due to their affordability and adequate heat transfer capabilities.

b. 3xxx Series Aluminum Plates

3xxx series aluminum plates contain manganese, making them even more corrosion-resistant than the 1xxx series. These plates are suitable for refrigerators located in humid environments or areas with high exposure to moisture.

c. 5xxx Series Aluminum Plates

5xxx series aluminum plates, specifically alloy 5052, offer exceptional strength and corrosion resistance. These plates are ideal for heavy-duty refrigerators or commercial applications where durability is crucial.

d. 6xxx Series Aluminum Plates

6xxx series aluminum plates, particularly alloy 6061, are renowned for their structural integrity and high strength-to-weight ratio. These plates are commonly used in premium refrigerators that require lightweight components without compromising on durability.

5. Frequently Asked Questions (FAQs)

a. What is the ideal thickness for an aluminum plate in a refrigerator?

The ideal thickness of an aluminum plate for a refrigerator generally ranges from 1.0mm to 3.0mm, depending on the size and purpose of the refrigerator. Thicker plates are preferred for larger refrigerators or those subjected to heavy usage.

b. How does the heat transfer capability of different aluminum plates vary?

Different aluminum plates have varying thermal conductivities, with higher conductivity resulting in better heat transfer. Consult the manufacturer's specifications to identify plates with superior heat transfer capabilities.

c. Can aluminum plates resist corrosion effectively?

Yes, aluminum plates can resist corrosion effectively, especially if they are coated or made from alloys with enhanced corrosion resistance properties. Consider plates from the 3xxx or 5xxx series for optimal corrosion resistance.

d. Does the weight of the aluminum plate impact refrigerator performance?

The weight of the aluminum plate affects the overall weight of the refrigerator, potentially impacting energy consumption and structural integrity. Opt for lightweight plates with high strength-to-weight ratios for optimal refrigerator performance.

e. Are there any specific regulations for using aluminum plates in refrigerators?

Specific regulations may vary by region, but generally, aluminum plates used in refrigerators should adhere to relevant safety standards and be free from any harmful substances that could contaminate food or compromise consumer safety.

6. Conclusion: Making the Right Choice for Optimal Refrigerator Performance

When it comes to choosing the right aluminum plate for your refrigerator, prioritize factors such as thickness, heat transfer capability, corrosion resistance, and weight. By selecting an aluminum plate that meets these criteria, you can ensure optimal refrigerator performance, improved energy efficiency, and the longevity of your appliance. Remember to consult with manufacturers or experts for specific recommendations based on your refrigerator's requirements.

1. Introduction: Understanding the Importance of Aluminum Plates in Refrigerators

2. The Role of Aluminum Plates in Refrigerator Efficiency

3. Factors to Consider When Choosing an Aluminum Plate

a. Thickness and Strength

b. Heat Transfer Capability

c. Corrosion Resistance

d. Weight and Structural Integrity

4. Different Types of Aluminum Plates for Refrigerators

a. 1xxx Series Aluminum Plates

b. 3xxx Series Aluminum Plates

c. 5xxx Series Aluminum Plates

d. 6xxx Series Aluminum Plates

5. Frequently Asked Questions (FAQs)

a. What is the ideal thickness for an aluminum plate in a refrigerator?

b. How does the heat transfer capability of different aluminum plates vary?

c. Can aluminum plates resist corrosion effectively?

d. Does the weight of the aluminum plate impact refrigerator performance?

e. Are there any specific regulations for using aluminum plates in refrigerators?

6. Conclusion: Making the Right Choice for Optimal Refrigerator Performance

1. Introduction: Understanding the Importance of Aluminum Plates in Refrigerators

In the world of modern refrigeration, aluminum plates play a vital role in ensuring optimal performance and efficiency. These plates are used for various applications, including heat exchange, structural support, and even aesthetic enhancements. Choosing the right aluminum plate is crucial to maximize the performance and longevity of your refrigerator.

2. The Role of Aluminum Plates in Refrigerator Efficiency

Aluminum plates are primarily responsible for facilitating heat transfer within refrigerators. These plates act as conductors, absorbing heat from the interior of the refrigerator and releasing it to the surrounding environment. By efficiently transferring heat, aluminum plates help maintain a stable temperature inside the refrigerator, ensuring the freshness and longevity of stored food.

3. Factors to Consider When Choosing an Aluminum Plate

a. Thickness and Strength

The thickness and strength of an aluminum plate are critical factors to consider. Thicker plates offer better structural integrity and durability, ensuring long-term performance. Additionally, thicker plates can withstand higher pressure differentials, making them suitable for heavy-duty refrigerators.

b. Heat Transfer Capability

The heat transfer capability of an aluminum plate determines its efficiency in absorbing and dissipating heat. Look for plates with high thermal conductivity, as they will facilitate faster heat exchange, leading to improved refrigerator efficiency and reduced energy consumption.

c. Corrosion Resistance

Refrigerators are exposed to moisture and various chemical agents, making corrosion resistance a vital consideration. Opt for aluminum plates with a protective coating or alloys that offer excellent corrosion resistance, ensuring the longevity of both the plate and the refrigerator.

d. Weight and Structural Integrity

The weight of the aluminum plate affects the overall weight of the refrigerator. Lighter plates are preferred, as they reduce the load on the refrigerator's components without compromising structural integrity. Consider plates with high strength-to-weight ratios for optimal performance.

4. Different Types of Aluminum Plates for Refrigerators

a. 1xxx Series Aluminum Plates

1xxx series aluminum plates are pure aluminum, known for their excellent corrosion resistance and thermal conductivity. These plates are commonly used in refrigerators due to their affordability and adequate heat transfer capabilities.

b. 3xxx Series Aluminum Plates

3xxx series aluminum plates contain manganese, making them even more corrosion-resistant than the 1xxx series. These plates are suitable for refrigerators located in humid environments or areas with high exposure to moisture.

c. 5xxx Series Aluminum Plates

5xxx series aluminum plates, specifically alloy 5052, offer exceptional strength and corrosion resistance. These plates are ideal for heavy-duty refrigerators or commercial applications where durability is crucial.

d. 6xxx Series Aluminum Plates

6xxx series aluminum plates, particularly alloy 6061, are renowned for their structural integrity and high strength-to-weight ratio. These plates are commonly used in premium refrigerators that require lightweight components without compromising on durability.

5. Frequently Asked Questions (FAQs)

a. What is the ideal thickness for an aluminum plate in a refrigerator?

The ideal thickness of an aluminum plate for a refrigerator generally ranges from 1.0mm to 3.0mm, depending on the size and purpose of the refrigerator. Thicker plates are preferred for larger refrigerators or those subjected to heavy usage.

b. How does the heat transfer capability of different aluminum plates vary?

Different aluminum plates have varying thermal conductivities, with higher conductivity resulting in better heat transfer. Consult the manufacturer's specifications to identify plates with superior heat transfer capabilities.

c. Can aluminum plates resist corrosion effectively?

Yes, aluminum plates can resist corrosion effectively, especially if they are coated or made from alloys with enhanced corrosion resistance properties. Consider plates from the 3xxx or 5xxx series for optimal corrosion resistance.

d. Does the weight of the aluminum plate impact refrigerator performance?

The weight of the aluminum plate affects the overall weight of the refrigerator, potentially impacting energy consumption and structural integrity. Opt for lightweight plates with high strength-to-weight ratios for optimal refrigerator performance.

e. Are there any specific regulations for using aluminum plates in refrigerators?

Specific regulations may vary by region, but generally, aluminum plates used in refrigerators should adhere to relevant safety standards and be free from any harmful substances that could contaminate food or compromise consumer safety.

6. Conclusion: Making the Right Choice for Optimal Refrigerator Performance

When it comes to choosing the right aluminum plate for your refrigerator, prioritize factors such as thickness, heat transfer capability, corrosion resistance, and weight. By selecting an aluminum plate that meets these criteria, you can ensure optimal refrigerator performance, improved energy efficiency, and the longevity of your appliance. Remember to consult with manufacturers or experts for specific recommendations based on your refrigerator's requirements.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.