Heat Exchanger Plates: Enhancing Efficiency in Industrial Heat Transfer

Introduction: Heat exchanger plates are fundamental components of industrial equipment that specialize in transferring heat between two fluids, ensuring efficient processes across various industries. These plates facilitate the exchange of thermal energy by maximizing the surface area available for heat transfer. In this article, we will explore the significance of heat exchanger plates, their app

Published:

2024-01-24

source:

author:

Introduction:

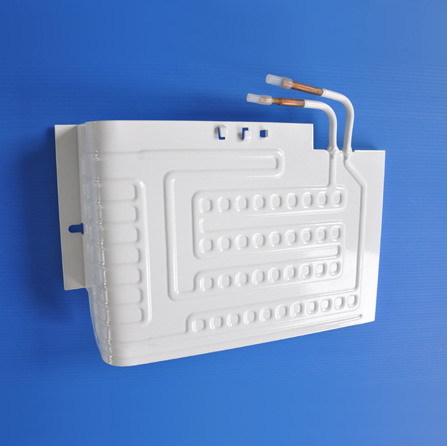

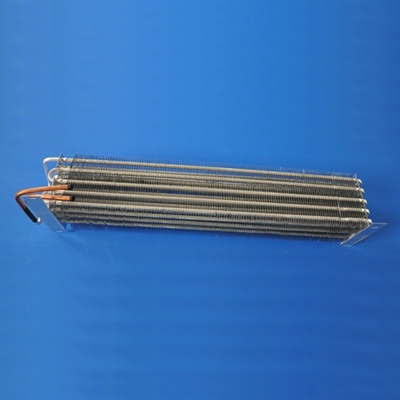

Heat exchanger plates are fundamental components of industrial equipment that specialize in transferring heat between two fluids, ensuring efficient processes across various industries. These plates facilitate the exchange of thermal energy by maximizing the surface area available for heat transfer. In this article, we will explore the significance of heat exchanger plates, their applications, benefits, and key factors to consider when choosing the right plate for your industrial heat exchange needs.

1. Applications:

Heat exchanger plates find widespread usage in diverse industries, including chemical, oil and gas, power generation, HVAC, food and beverage, and many more. These plates are employed in applications such as:

- Heating and cooling processes

- Energy recovery systems

- Heat pumps and refrigeration

- Waste heat recovery

- Condensation and evaporation

- Pasteurization and sterilization

2. Benefits of Heat Exchanger Plates:

Heat exchanger plates offer several advantages that contribute to enhanced efficiency and cost-effectiveness in heat transfer applications. Some key benefits include:

- High heat transfer coefficients: The unique design of heat exchanger plates promotes turbulent flow, resulting in improved thermal performance.

- Compact size: Heat exchanger plates allow for a significant reduction in size and weight compared to traditional heat exchanger designs, saving valuable space.

- Flexibility and scalability: The modular nature of heat exchanger plates enables easy customization and expansion based on specific requirements.

- Reduced maintenance costs: The design minimizes fouling and scaling, reducing the need for frequent cleaning and maintenance.

- Energy efficiency: Heat exchanger plates optimize heat recovery and minimize energy consumption, leading to cost savings.

3. Factors to Consider:

When selecting heat exchanger plates for your industrial equipment, consider the following factors:

- Fluid compatibility: Ensure that the materials used for the plates are compatible with the fluids being processed to prevent corrosion or contamination.

- Thermal performance: Evaluate the heat transfer efficiency and pressure drop characteristics of the plates to meet your specific application requirements.

- Plate design and pattern: Different plate designs (e.g., corrugated, dimpled, or plain) and patterns (e.g., parallel or diagonal) offer varying performance advantages. Choose the most suitable design for your needs.

- Cleaning and maintenance: Consider the ease of cleaning and the accessibility of the plates for maintenance purposes to minimize downtime and associated costs.

- Plate thickness and material: The choice of plate thickness and material affects the durability, resistance to corrosion, and thermal conductivity of the plates.

In conclusion, heat exchanger plates are indispensable components in industrial heat transfer equipment. They provide numerous benefits, including high thermal efficiency, compactness, and energy savings. By considering the appropriate factors during the selection process, you can optimize heat transfer operations in your industrial applications. Embrace the potential of heat exchanger plates to enhance efficiency and productivity in your industry.

Heat exchanger plates are fundamental components of industrial equipment that specialize in transferring heat between two fluids, ensuring efficient processes across various industries. These plates facilitate the exchange of thermal energy by maximizing the surface area available for heat transfer. In this article, we will explore the significance of heat exchanger plates, their applications, benefits, and key factors to consider when choosing the right plate for your industrial heat exchange needs.

1. Applications:

Heat exchanger plates find widespread usage in diverse industries, including chemical, oil and gas, power generation, HVAC, food and beverage, and many more. These plates are employed in applications such as:

- Heating and cooling processes

- Energy recovery systems

- Heat pumps and refrigeration

- Waste heat recovery

- Condensation and evaporation

- Pasteurization and sterilization

2. Benefits of Heat Exchanger Plates:

Heat exchanger plates offer several advantages that contribute to enhanced efficiency and cost-effectiveness in heat transfer applications. Some key benefits include:

- High heat transfer coefficients: The unique design of heat exchanger plates promotes turbulent flow, resulting in improved thermal performance.

- Compact size: Heat exchanger plates allow for a significant reduction in size and weight compared to traditional heat exchanger designs, saving valuable space.

- Flexibility and scalability: The modular nature of heat exchanger plates enables easy customization and expansion based on specific requirements.

- Reduced maintenance costs: The design minimizes fouling and scaling, reducing the need for frequent cleaning and maintenance.

- Energy efficiency: Heat exchanger plates optimize heat recovery and minimize energy consumption, leading to cost savings.

3. Factors to Consider:

When selecting heat exchanger plates for your industrial equipment, consider the following factors:

- Fluid compatibility: Ensure that the materials used for the plates are compatible with the fluids being processed to prevent corrosion or contamination.

- Thermal performance: Evaluate the heat transfer efficiency and pressure drop characteristics of the plates to meet your specific application requirements.

- Plate design and pattern: Different plate designs (e.g., corrugated, dimpled, or plain) and patterns (e.g., parallel or diagonal) offer varying performance advantages. Choose the most suitable design for your needs.

- Cleaning and maintenance: Consider the ease of cleaning and the accessibility of the plates for maintenance purposes to minimize downtime and associated costs.

- Plate thickness and material: The choice of plate thickness and material affects the durability, resistance to corrosion, and thermal conductivity of the plates.

In conclusion, heat exchanger plates are indispensable components in industrial heat transfer equipment. They provide numerous benefits, including high thermal efficiency, compactness, and energy savings. By considering the appropriate factors during the selection process, you can optimize heat transfer operations in your industrial applications. Embrace the potential of heat exchanger plates to enhance efficiency and productivity in your industry.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.