Choosing the Right Refrigeration Evaporator for Your Industrial Needs

Table of Contents: 1. Introduction: Understanding the Significance of a Refrigeration Evaporator 2. Types of Refrigeration Evaporators 2.1 Forced Air Evaporators 2.2 Liquid Overfeed Evaporators 2.3 Gravity Coil Evaporators 2.4 Plate Evaporators 2.5 Shell and Tube Evaporators 2.6 Finned Evaporators 2.7 Coils-in-Series Evaporators 2.8 Flooded Shell Evaporators 3. Factors to C

Published:

2024-01-18

source:

author:

Table of Contents:

1. Introduction: Understanding the Significance of a Refrigeration Evaporator

2. Types of Refrigeration Evaporators

2.1 Forced Air Evaporators

2.2 Liquid Overfeed Evaporators

2.3 Gravity Coil Evaporators

2.4 Plate Evaporators

2.5 Shell and Tube Evaporators

2.6 Finned Evaporators

2.7 Coils-in-Series Evaporators

2.8 Flooded Shell Evaporators

3. Factors to Consider when Choosing a Refrigeration Evaporator

3.1 Cooling Capacity

3.2 Space and Installation Constraints

3.3 Energy Efficiency

3.4 Maintenance and Cleanliness

3.5 Compatibility with Refrigerants

3.6 Customization Options

3.7 Cost-effectiveness

4. Frequently Asked Questions (FAQs)

4.1 What is the purpose of a refrigeration evaporator?

4.2 How does a forced air evaporator work?

4.3 Which type of evaporator is best for small spaces?

4.4 Can a refrigeration evaporator be used with different refrigerants?

4.5 What maintenance is required for a refrigeration evaporator?

5. Conclusion

1. Introduction: Understanding the Significance of a Refrigeration Evaporator

Refrigeration evaporators play a crucial role in industrial cooling systems by absorbing heat from the surroundings and facilitating the cooling process. Selecting the right evaporator is essential for maximizing cooling efficiency and maintaining product integrity.

2. Types of Refrigeration Evaporators

2.1 Forced Air Evaporators

Forced air evaporators use fans to circulate air over the evaporator coil, enhancing heat transfer. They are commonly used in commercial refrigeration units due to their uniform cooling capabilities.

2.2 Liquid Overfeed Evaporators

Liquid overfeed evaporators utilize a continuous flow of liquid refrigerant over the evaporator coil, improving cooling efficiency. They are suitable for large-scale industrial applications that require precise temperature control.

2.3 Gravity Coil Evaporators

Gravity coil evaporators rely on gravity to distribute liquid refrigerant evenly across the evaporator coil. They are commonly used in walk-in coolers and freezers, providing efficient cooling in medium-sized spaces.

2.4 Plate Evaporators

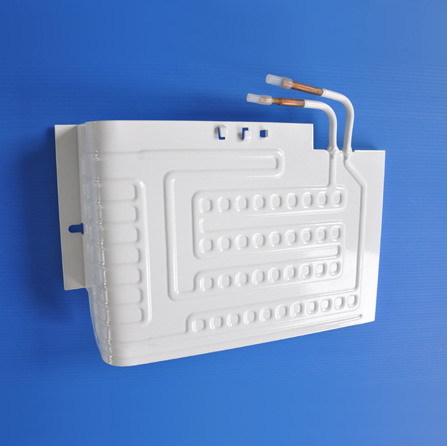

Plate evaporators consist of a series of plates with refrigerant flowing between them. These evaporators offer high heat transfer efficiency and are ideal for applications with limited space.

2.5 Shell and Tube Evaporators

Shell and tube evaporators employ a series of tubes within a shell, facilitating heat exchange between the refrigerant and the surrounding medium. They are widely used in industrial cooling systems.

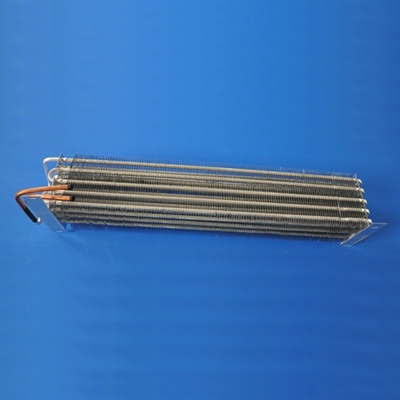

2.6 Finned Evaporators

Finned evaporators feature fins on the evaporator coil surface to increase the heat transfer area, improving cooling efficiency. They are commonly used in air conditioning systems and refrigerated display cases.

2.7 Coils-in-Series Evaporators

Coils-in-series evaporators consist of multiple evaporator coils connected in series. This configuration enables precise cooling control and is often utilized in critical industrial applications.

2.8 Flooded Shell Evaporators

Flooded shell evaporators submerge the evaporator tubes in liquid refrigerant, ensuring efficient heat transfer. They are suitable for large-scale industrial refrigeration systems.

3. Factors to Consider when Choosing a Refrigeration Evaporator

3.1 Cooling Capacity

Assess your cooling requirements and choose an evaporator that can efficiently handle the desired cooling capacity while maintaining optimal temperature levels.

3.2 Space and Installation Constraints

Consider the available space and installation requirements. Select an evaporator that fits within the allocated space and can be installed seamlessly with the existing refrigeration system.

3.3 Energy Efficiency

Opt for an energy-efficient evaporator to reduce operating costs and minimize environmental impact. Look for energy-saving features such as variable speed fans or advanced heat transfer technologies.

3.4 Maintenance and Cleanliness

Choose an evaporator that is easy to clean and maintain. Regular maintenance ensures optimal performance and prolongs the lifespan of the equipment.

3.5 Compatibility with Refrigerants

Ensure the chosen evaporator is compatible with the specific refrigerant used in your cooling system. Different evaporator designs may require specific refrigerant types for optimal functioning.

3.6 Customization Options

Consider the flexibility of customization options offered by the evaporator manufacturer. Customizable features can better cater to your unique cooling requirements.

3.7 Cost-effectiveness

Evaluate the long-term costs associated with the evaporator, including initial investment, operating expenses, maintenance, and potential energy savings. Choose a cost-effective option that aligns with your budget.

4. Frequently Asked Questions (FAQs)

4.1 What is the purpose of a refrigeration evaporator?

A refrigeration evaporator absorbs heat from the surroundings, facilitating the cooling process in industrial refrigeration systems.

4.2 How does a forced air evaporator work?

A forced air evaporator uses fans to circulate air over the evaporator coil, enhancing heat transfer and providing uniform cooling.

4.3 Which type of evaporator is best for small spaces?

Gravity coil evaporators are often the preferred choice for small spaces, such as walk-in coolers or freezers, due to their efficient cooling capabilities.

4.4 Can a refrigeration evaporator be used with different refrigerants?

Yes, the compatibility of a refrigeration evaporator with different refrigerants depends on its design and specifications. Consult with the manufacturer to ensure compatibility.

4.5 What maintenance is required for a refrigeration evaporator?

Regular cleaning and inspection are necessary to maintain optimal performance. This includes removing dust, debris, and ice buildup from the evaporator coil.

5. Conclusion

Selecting the right refrigeration evaporator is crucial for optimizing your industrial cooling system. Consider factors such as cooling capacity, space constraints, energy efficiency, and maintenance requirements to make an informed decision. By choosing the appropriate evaporator, you can ensure efficient cooling, reduce operating costs, and prolong the lifespan of your equipment.

1. Introduction: Understanding the Significance of a Refrigeration Evaporator

2. Types of Refrigeration Evaporators

2.1 Forced Air Evaporators

2.2 Liquid Overfeed Evaporators

2.3 Gravity Coil Evaporators

2.4 Plate Evaporators

2.5 Shell and Tube Evaporators

2.6 Finned Evaporators

2.7 Coils-in-Series Evaporators

2.8 Flooded Shell Evaporators

3. Factors to Consider when Choosing a Refrigeration Evaporator

3.1 Cooling Capacity

3.2 Space and Installation Constraints

3.3 Energy Efficiency

3.4 Maintenance and Cleanliness

3.5 Compatibility with Refrigerants

3.6 Customization Options

3.7 Cost-effectiveness

4. Frequently Asked Questions (FAQs)

4.1 What is the purpose of a refrigeration evaporator?

4.2 How does a forced air evaporator work?

4.3 Which type of evaporator is best for small spaces?

4.4 Can a refrigeration evaporator be used with different refrigerants?

4.5 What maintenance is required for a refrigeration evaporator?

5. Conclusion

1. Introduction: Understanding the Significance of a Refrigeration Evaporator

Refrigeration evaporators play a crucial role in industrial cooling systems by absorbing heat from the surroundings and facilitating the cooling process. Selecting the right evaporator is essential for maximizing cooling efficiency and maintaining product integrity.

2. Types of Refrigeration Evaporators

2.1 Forced Air Evaporators

Forced air evaporators use fans to circulate air over the evaporator coil, enhancing heat transfer. They are commonly used in commercial refrigeration units due to their uniform cooling capabilities.

2.2 Liquid Overfeed Evaporators

Liquid overfeed evaporators utilize a continuous flow of liquid refrigerant over the evaporator coil, improving cooling efficiency. They are suitable for large-scale industrial applications that require precise temperature control.

2.3 Gravity Coil Evaporators

Gravity coil evaporators rely on gravity to distribute liquid refrigerant evenly across the evaporator coil. They are commonly used in walk-in coolers and freezers, providing efficient cooling in medium-sized spaces.

2.4 Plate Evaporators

Plate evaporators consist of a series of plates with refrigerant flowing between them. These evaporators offer high heat transfer efficiency and are ideal for applications with limited space.

2.5 Shell and Tube Evaporators

Shell and tube evaporators employ a series of tubes within a shell, facilitating heat exchange between the refrigerant and the surrounding medium. They are widely used in industrial cooling systems.

2.6 Finned Evaporators

Finned evaporators feature fins on the evaporator coil surface to increase the heat transfer area, improving cooling efficiency. They are commonly used in air conditioning systems and refrigerated display cases.

2.7 Coils-in-Series Evaporators

Coils-in-series evaporators consist of multiple evaporator coils connected in series. This configuration enables precise cooling control and is often utilized in critical industrial applications.

2.8 Flooded Shell Evaporators

Flooded shell evaporators submerge the evaporator tubes in liquid refrigerant, ensuring efficient heat transfer. They are suitable for large-scale industrial refrigeration systems.

3. Factors to Consider when Choosing a Refrigeration Evaporator

3.1 Cooling Capacity

Assess your cooling requirements and choose an evaporator that can efficiently handle the desired cooling capacity while maintaining optimal temperature levels.

3.2 Space and Installation Constraints

Consider the available space and installation requirements. Select an evaporator that fits within the allocated space and can be installed seamlessly with the existing refrigeration system.

3.3 Energy Efficiency

Opt for an energy-efficient evaporator to reduce operating costs and minimize environmental impact. Look for energy-saving features such as variable speed fans or advanced heat transfer technologies.

3.4 Maintenance and Cleanliness

Choose an evaporator that is easy to clean and maintain. Regular maintenance ensures optimal performance and prolongs the lifespan of the equipment.

3.5 Compatibility with Refrigerants

Ensure the chosen evaporator is compatible with the specific refrigerant used in your cooling system. Different evaporator designs may require specific refrigerant types for optimal functioning.

3.6 Customization Options

Consider the flexibility of customization options offered by the evaporator manufacturer. Customizable features can better cater to your unique cooling requirements.

3.7 Cost-effectiveness

Evaluate the long-term costs associated with the evaporator, including initial investment, operating expenses, maintenance, and potential energy savings. Choose a cost-effective option that aligns with your budget.

4. Frequently Asked Questions (FAQs)

4.1 What is the purpose of a refrigeration evaporator?

A refrigeration evaporator absorbs heat from the surroundings, facilitating the cooling process in industrial refrigeration systems.

4.2 How does a forced air evaporator work?

A forced air evaporator uses fans to circulate air over the evaporator coil, enhancing heat transfer and providing uniform cooling.

4.3 Which type of evaporator is best for small spaces?

Gravity coil evaporators are often the preferred choice for small spaces, such as walk-in coolers or freezers, due to their efficient cooling capabilities.

4.4 Can a refrigeration evaporator be used with different refrigerants?

Yes, the compatibility of a refrigeration evaporator with different refrigerants depends on its design and specifications. Consult with the manufacturer to ensure compatibility.

4.5 What maintenance is required for a refrigeration evaporator?

Regular cleaning and inspection are necessary to maintain optimal performance. This includes removing dust, debris, and ice buildup from the evaporator coil.

5. Conclusion

Selecting the right refrigeration evaporator is crucial for optimizing your industrial cooling system. Consider factors such as cooling capacity, space constraints, energy efficiency, and maintenance requirements to make an informed decision. By choosing the appropriate evaporator, you can ensure efficient cooling, reduce operating costs, and prolong the lifespan of your equipment.

Hot News

Mobile website

language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

Tel: 0086-13775291367

E-mail: michael@xinxincool.com

ADD:No. 32 Tianshan Road, Xinqiao Town, Xinbei District, Changzhou City, Jiangsu Province

Copyright © 2024 Changzhou Xinxin Refrigeration Equipment Co., Ltd.